Water Cooled Cable

Water-cooled power leads are essential components of induction equipment, crucial for maintaining optimal performance and preventing overheating issues. Lawatherm offers customizable water-cooled cables designed to address specific needs and applications. Constructed with high-quality materials, these cables ensure efficient power transfer and heat dissipation, vital for the smooth operation of induction systems in various industries.

Get in touch

Water Cooled Cable Products Collection

WATER-COOLED POWERLEADS

Water-cooled power leads are essential components of induction equipment, ensuring optimal performance by effectively dissipating heat generated during operation. At Lawatherm, we offer comprehensive solutions for water-cooled power leads, addressing commonissues such as overheating coils resulting from restricted water flow. Our expertise lies in the manufacturing, rebuilding, and customization of power leads tailored to specific applications.

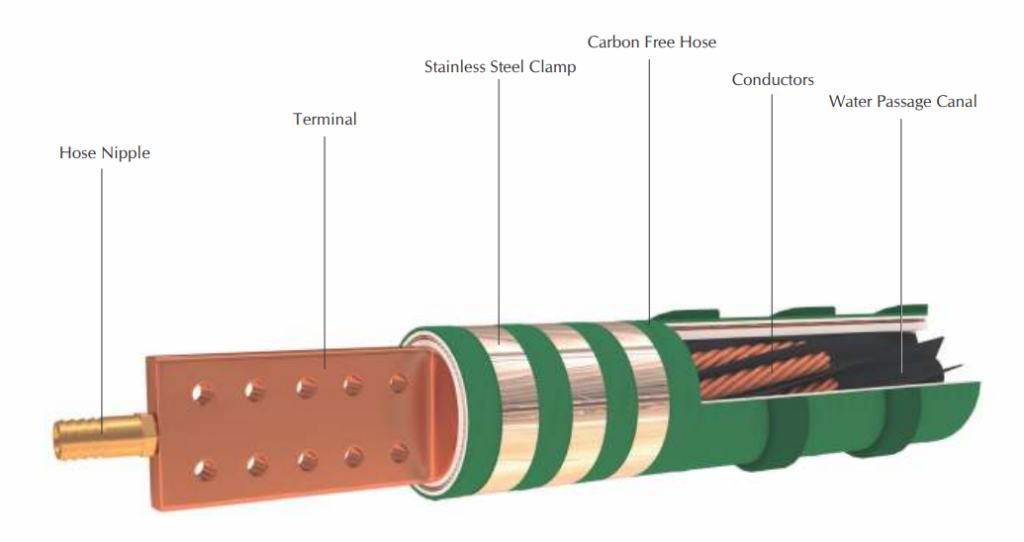

Constructed with high flexibility and toughness, our power leads facilitate easy passage through hoses while maintaining superior electrical conductivity. Utilizing copper with 101% electrical conductivity, soldered to terminals for maximum contact and efficiency, our cables guarantee reliable performance.

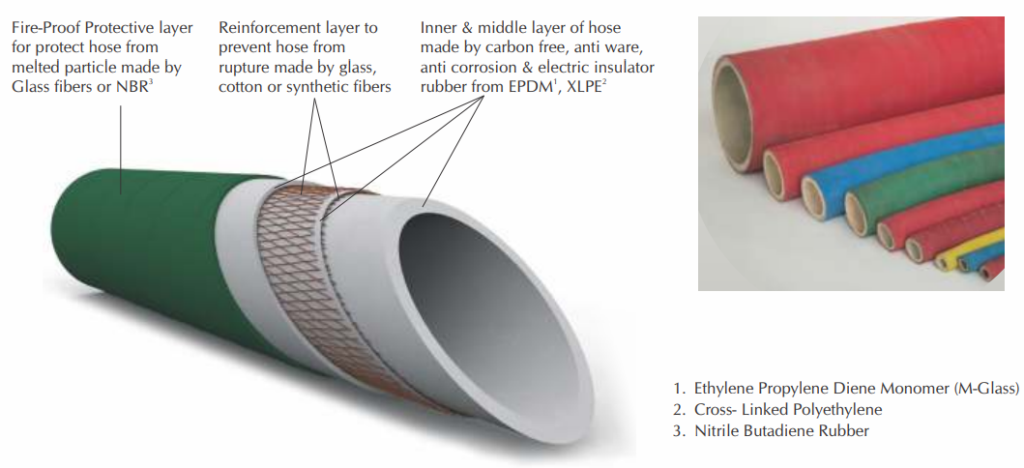

Encased in a non-conductive hose featuring a nitrile tube, reinforced center, and neoprene cover, our cables are protected against damage from heated materials. With a minimum burst pressure of 1000 psi and continuous operating pressure of 250 psi, our cables ensure durability and safety in demanding environments.

Our flange-type terminals, resurfaced and silver-plated for optimum conductivity, offer long-lasting performance. Designed to withstand abrasion and weather, our carbon-free hoses are ideal for use in electrical induction furnaces, providing protection against high temperatures, current leakage, and radiation exposure.

WATER COOLED CABLES

Water-cooled cables play a crucial role in transferring electrical power from the source to the crucible of a furnace. Designed to withstand high currents and heat, our water-cooled cables ensure efficient power transmission while effectively dissipating heat through water flow.

Lawatherm specializes in the design and manufacture of a diverse range of water-cooled cables, employing advanced materials and innovative designs to meet varying requirements. Our cables are categorized based on their composition and arrangement of conductors, offering options tailored to specific applications and usage scenarios.

CONDUCTORS

Our water-cooled cables feature conductors composed of twisted copper wire strings, carefully selected for their conductivity and durability. Whether continuous or separated, our cables are engineered to deliver consistent performance, with symmetrical twist angles ensuring optimal efficiency.

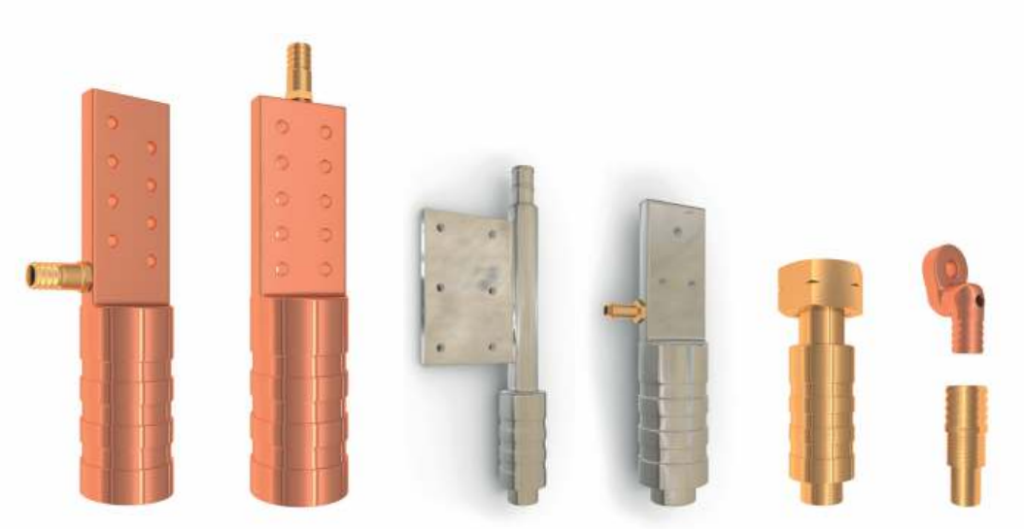

TERMINAL

Lawatherm produces high-quality cable heads for water-cooled cables, meticulously

crafted to meet precise specifications and performance standards. Using ETP grade copper, our terminals are forged and machined to ensure reliability and durability, minimizing the risk of failure, particularly in high-power applications.

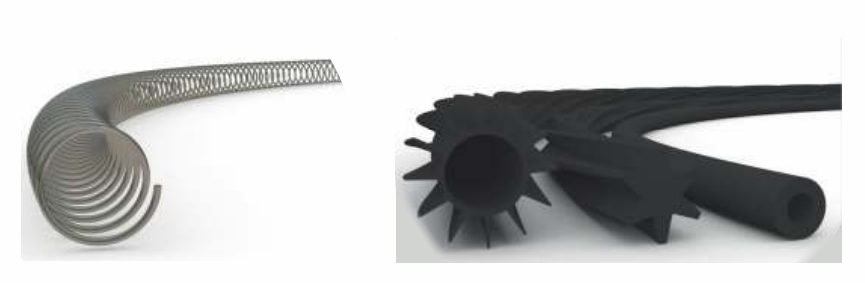

WATER PASSAGE

Water passage canals facilitate the flow of water through water-cooled cables, preventing disruptions caused by conductor irregularities. Available in spring-type or one-piece designs, our water passage solutions are engineered for durability and corrosion resistance, ensuring uninterrupted cooling performance.

HOSE CLAMPS

Lawatherm’s stainless steel hose clamps provide secure sealing for water-cooled cable hoses, ensuring reliable performance under challenging conditions. Designed for easy installation and durability, our toothless clamps prevent heating under magnetic fields, guaranteeing long-term reliability and safety.

HOSE

Our hoses for water-cooled cables are engineered for durability and reliability, constructed from carbon-free materials resistant to corrosion. Reinforced with woven synthetic fibers, our hoses offer exceptional tear resistance while maintaining flexibility. Additionally, a fireproof outer layer provides added protection in demanding environments.

Advantages of Water Cooled Cable

- Superior heat dissipation: Water cooling effectively prevents overheating of coils, ensuring reliable performance.

- Customization options: Lawatherm provides tailored solutions to meet specific requirements, enhancing flexibility and versatility.

- Durable construction: Copper conductors with optimal conductivity and robust hose materials ensure long-lasting durability, even in harsh environments.

- Enhanced safety: Carbon-free hoses and stainless steel hose clamps minimize risks associated with exposure to high temperatures and electrical currents.

Construction of Water Cooled Cable

- Copper conductors: Twisted copper wire strings, predominantly bare or tin-plated, ensure optimal electrical conductivity.

- Hose materials: Non-conductive hoses constructed with nitrile tubes, multi-ply reinforcement, and neoprene covers protect heated materials and maintain structural integrity under pressure.

- Terminal heads: Flange-type terminals with silver plating ensure optimum contact and electrical conductivity.

- Water passage canals: Stainless steel or copper spring-type canals facilitate water flow through the cable, preventing obstruction by conductor ravels.

Specifications of Water-Cooled Cable

- Material: ETP grade copper for conductors; corrosion-resistant materials for hoses and terminal heads.

- Pressure ratings: Minimum burst pressure of 1000 psi, continuous operating pressure of 250 psi for hoses; maximum working pressure of 10 to 20 bars for cables.

- Conductivity: Copper conductors are rated at 101% electrical conductivity by the IACS.

- Dimensions: Customizable lengths and diameters to suit specific applications.

Applications of Water-Cooled Cable:

Water-cooled cables are indispensable for various industries, including:

- Steel and iron industries: Protection against exposure to high temperatures, current leakage, and radiation in induction furnaces.

- Manufacturing: Reliable power transfer for melting, casting, and heat treatment processes.

- Foundries: Efficient heat dissipation for maintaining optimal operating conditions in crucible furnaces.

Get in touch

Installation of Water Cooled Cable

- Follow manufacturer guidelines for cable routing and connection to ensure proper water flow and electrical conductivity.

- Secure hose clamps tightly to prevent leaks and ensure uninterrupted water flow.

- Conduct periodic inspections to detect and address any signs of wear or damage.

Maintenance of Water Cooled Cable

- Regularly inspect hoses, conductors, and terminal heads for signs of wear, corrosion, or damage.

- Flush water passages periodically to remove any debris or sediment that may obstruct water flow.

- Replace worn components promptly to prevent disruptions to induction system performance.

Safety Precautions

- Avoid contact with heated materials and electrical components during installation and maintenance.

- Ensure proper grounding and insulation to minimize the risk of electric shock.

- Use appropriate personal protective equipment, including heat-resistant gloves and eyewear, when handling hot surfaces.

Frequently Asked Questions

Water-cooled cables dissipate heat generated by high electrical currents through water flow, effectively cooling the system and preventing overheating.

Yes, Lawatherm offers customization options to tailor water-cooled cables to meet the unique requirements of different industries and applications.

Water-cooled cables typically have a minimum burst pressure of 1000 psi and a continuous operating pressure of 250 psi for optimal performance.

Regular inspections and maintenance are recommended to ensure the integrity and performance of water-cooled cables. Inspect cables periodically for signs of wear, corrosion, or damage, and address any issues promptly to prevent disruptions to system operation