Induction Furnace Spare

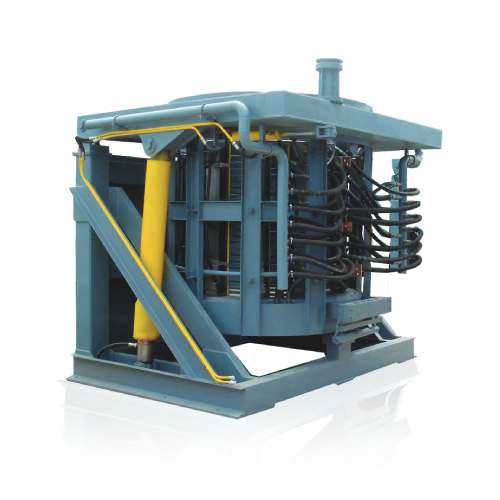

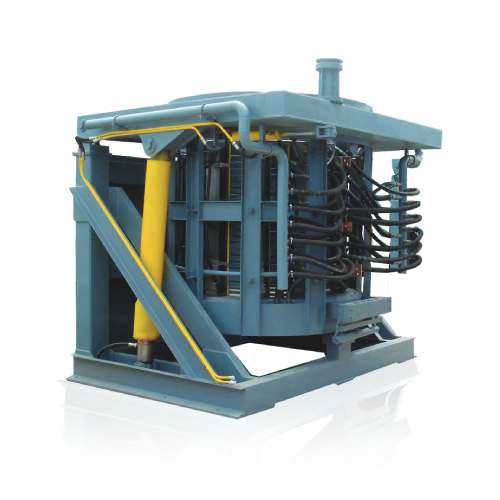

SOLID STATE GENERATOR PANEL

Lawatherm is a leading edge distributor of power electronic components like MF water cooled capacitor, SCR thyristors, Diodes, IGBT’s power module, semiconductor & HRC Fuse, Sunubber Capacitor & Resistor, Temperature sensor / switch / gauge / thermostat along with other passive components like analog / digital meter, connectors, LED and relays. A highly experienced team of engineers equipped with required infrastructure are always available to offer expert advice and services on a vast range of products and topics. Lawatherm holds in-depth stocks of a wide range of products including some of the best brands i.e. IXYS Westcode, ABB, Eupec, Proton, Copper Bussmann, Ferraz shamut, Gold, Yaco, RARA, ArcolUK, Kiyosh, Semikron, Hirect, Ruttonsha, and various other National & International companies and provide our clients the opportunity to single source their requirements. We are here to help! Our sales team is dedicated to customer service and offers technical advice to ensure the correct selection of product. We pride ourselves on our responsive and flexible approach to meeting our clients’ various needs and endeavour to maintain a close working relationship with those customers.

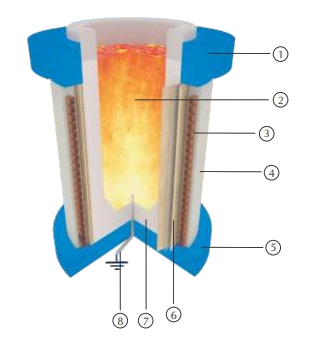

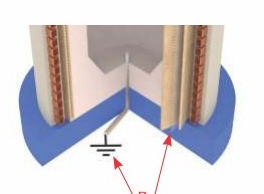

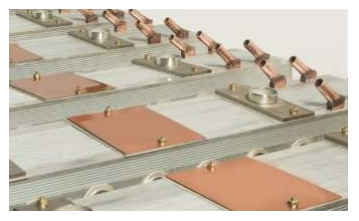

MF WATER COOLED CAPACITOR

MF water cooled capacitors are designed for very high levels of safety, reliability and life expectancy. Capacitors are provided with high thermal conductivity copper tubes, through which cooling water is circulated. The effective dissipation of heat by this method is extremely important to achieve desired performance and life expectancy levels. The water-cooled capacitors are generally enclosed in aluminum cases so as to avoid heating due to magnetic fields. Thus the capacitors run much cooler compared to those of conventional design. Their expected life is also longer. In the dead case construction the current returns through water-cooling terminals instead of through the capacitor case. This leads to longer capacitor life since less heat is generated in the case and absorbed by dielectric fluid. This construction permits, capacitor mounting directly to the chassis without insulators, permitting savings in installation expenses.

SEMICONDUCTOR & HRC FUSE

Semiconductor & HRC fuses are used to protect against over-current conditions in Semiconductor devices. Because of their fast action, semiconductor fuses help to limit short circuit current significantly.

Our products portfolio includes some of the best brands i.e. Copper Bussmann, Ferraz-Shawmut, Gold, Yaco, Simens, GE, and various other National & International companies and provide our clients the opportunity to single source their requirements.

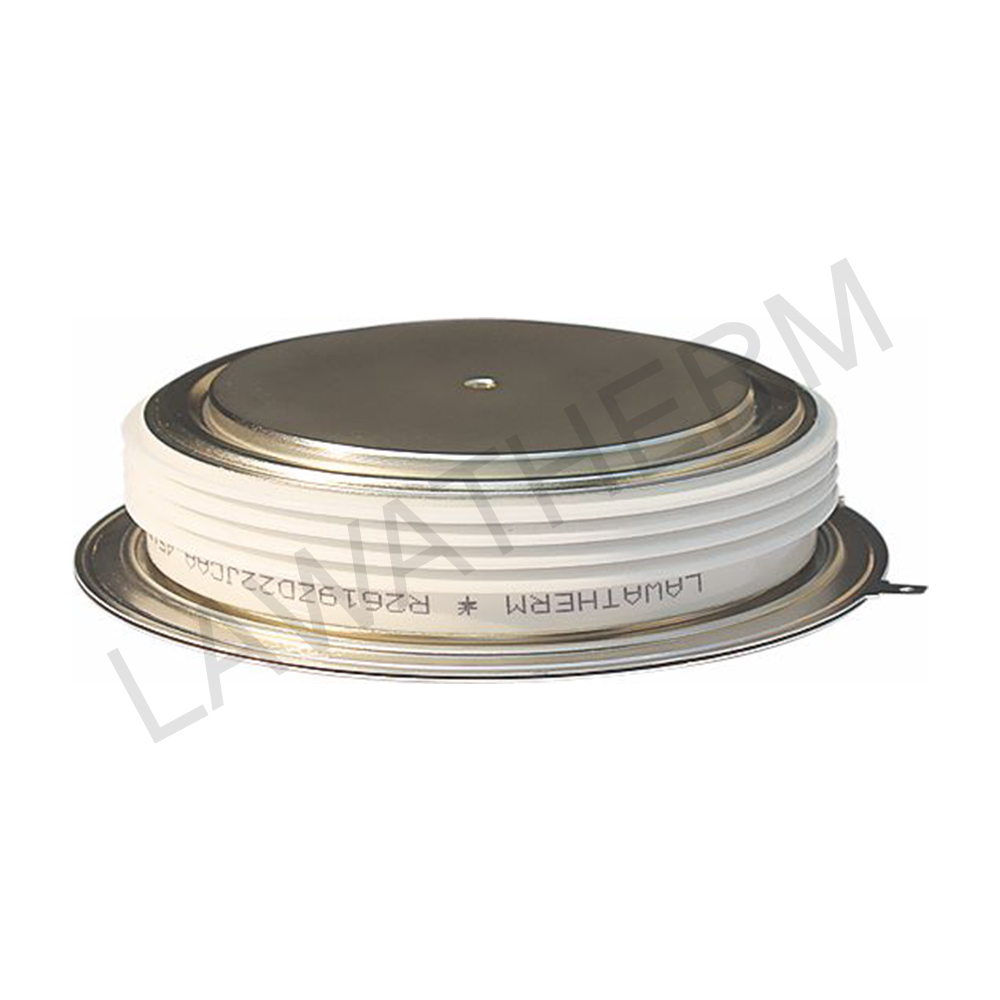

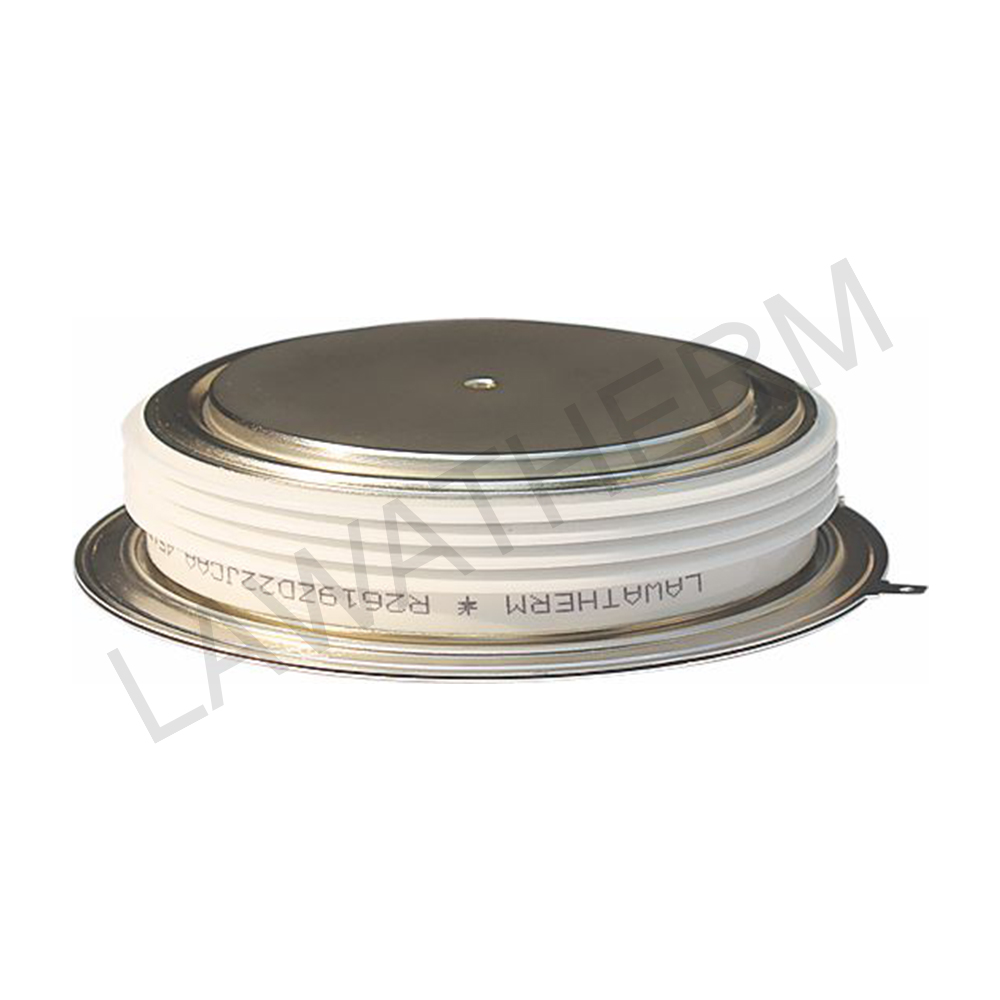

SCR INVERTER & CONVERTER THYRISTOR

Thyristors are “normally-off” switches that can be triggered “on” by a small current pulse into the gate electrode. Once turned on (or “triggered”), the component then stays in the conducting state even when the gate on-signal is removed. It only returns to the “off” (blocking) state if the current falls below a certain minimum or if the direction of the current is reversed. Some sources define silicon controlled rectifiers and thyristors as synonymous. Our products portfolio includes some of the best brands i.e. ABB, IXYS-Westcode, Epuec Proton-Electrotex, Semikron, Hirect, and various other National & International companies and provide our clients the opportunity to single source their requirements.

IGBT POWER MODULE

Module turns on by applying a pulse current to a gate current. However, because it is a latch type semiconductor, the thyristor only turns on when a sustained current (holding current) reaches a set level. To turn off in a DC circuit, the gate current must be reduced below the holding current or reverse voltage has to be applied using a commutation circuit. In an AC circuit, the pulse current has to be applied to the gate current whenever it is positive, because the gate current falls below the holding current and the thyristor turns off whenever the current alternates.

Our products portfolio includes some of the best brands i.e. ABB, IXYS-Westcode, Epuec Proton-Electrotex, Semikron Hirect, Ruttonsha and various other National & International companies and provide our clients the opportunity to single source their requirements

SNUBBER CAPACITOR

Snubbers are any of several simple energy absorbing circuits used to eliminate voltage spikes caused by circuit inductance when a switch— either mechanical or semi-conductor—opens. The object of the snubber is to eliminate the voltage transient and ringing that occurs when the switch opens by providing an alternate path for the current flowing through the circuit’s intrinsic leakage inductance. Snubbers in switch mode power supplies provide one or more of these three valuable functions.

Our products portfolio includes some of the best brands i.e. Arcotronics, GE Afcos and various other National & International companies and provide our clients the opportunity to single source their requirements.

WCR HIGH POWER RESISTOR

Water cooled resistor having been originally designed for thyristor protection circuit. Where water cooling is available and space limited. The withdrawal of heat, internally & externally ensure a low temperature gradient across the unit reducing internal stress. Heat is extracted internally through the cooling pipe & externally by direct mounting on to chassis or additional water cooled heat sink thereby reducing temperature gradient across internal insulation.

Our products portfolio includes some of the best brands i.e. Arcol, RARA, Kiyosh, raatronics and various other National & International companies and provide our clients the opportunity to single source their requirements

TEMPERATURE SENSOR / GAUGE

Temp sensor convert a temperature change into mechanical displacement, are the most recognized bimetallic objects due to their name. Lawatherm has been leading manufacturers in the field of thermal regulation and protection with a wide range of plate and Disc type bimetallic thermostats.

These snap-action devices, with Quick Make/ Quick Break action, automatically manual reset with Brass Round mounting stud of M4 X 0.7 mm threads at preset temperature. An electrically isolated bimetal disc is used to either open or close the circuit current. Rating: 10Amps250VAc

Temperature: 40 to 190°C (At 10°C interval). Our products portfolio includes some of the best brands i.e. Honeywell, Lawatherm, Elmwood and various other National & International companies and provide our clients the opportunity to single source their requirements

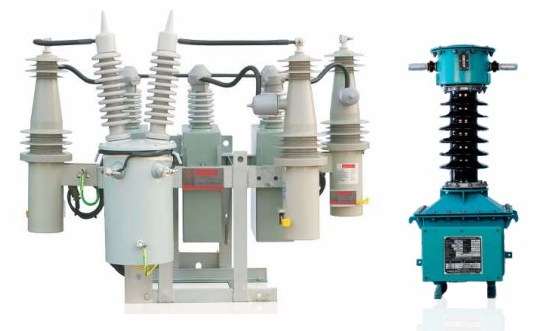

CONTROL TRANSFORMER

Transformer is a static electrical device that transfers energy by inductive coupling between its winding circuits. A varying current in the primary winding creates a varying magnetic flux in the transformer’s core and thus a varying magnetic flux through the secondary winding. This varying magnetic flux induces a varying electromotive force (EMF) or voltage in the secondary winding. Lawatherm offers a complete line of Industrial Control Transformers, which provide stepped-down voltages to machine tool control devices. Each unit must pass rigid tests for turns ratio, insulation, continuity, and over potential. Performance meets or exceeds ANSI/NEMA ST-1 requirements. With a 50-60 Hz operation standard, transformers are designed for loads requiring extremely good regulation. Regulation also exceeds ANSI/NEMA requirements.

DIODE

The most common function of a diode is to allow an electric current to pass in one direction (called the diode’s forward direction), while blocking current in the opposite direction (the reverse direction). Thus, the diode can be viewed as an electronic version of a check valve. This unidirectional behavior is called rectification, and is used to convert alternating current to direct current, including extraction of modulation from radio signals in

radio receivers—these diodes are forms of rectifiers. Our products portfolio includes some of the best brands i.e. ABB, IXYS-Westcode, Epuec Proton-Electrotex, Semikron, Hirect, Ruttonsha and various other National & International companies and provide our clients the opportunity to single source their requirements

CRUCIBLE SPARES

We offer clients a wide range of precision finished crucible spares. Based on latest technology based processes, these are available in form of flow switches, change over switches, hose clamps, water cooled cables, silicon lamination cores and others. Our process expertise also allow us to deliver these in specific finishes as defined by the clients.

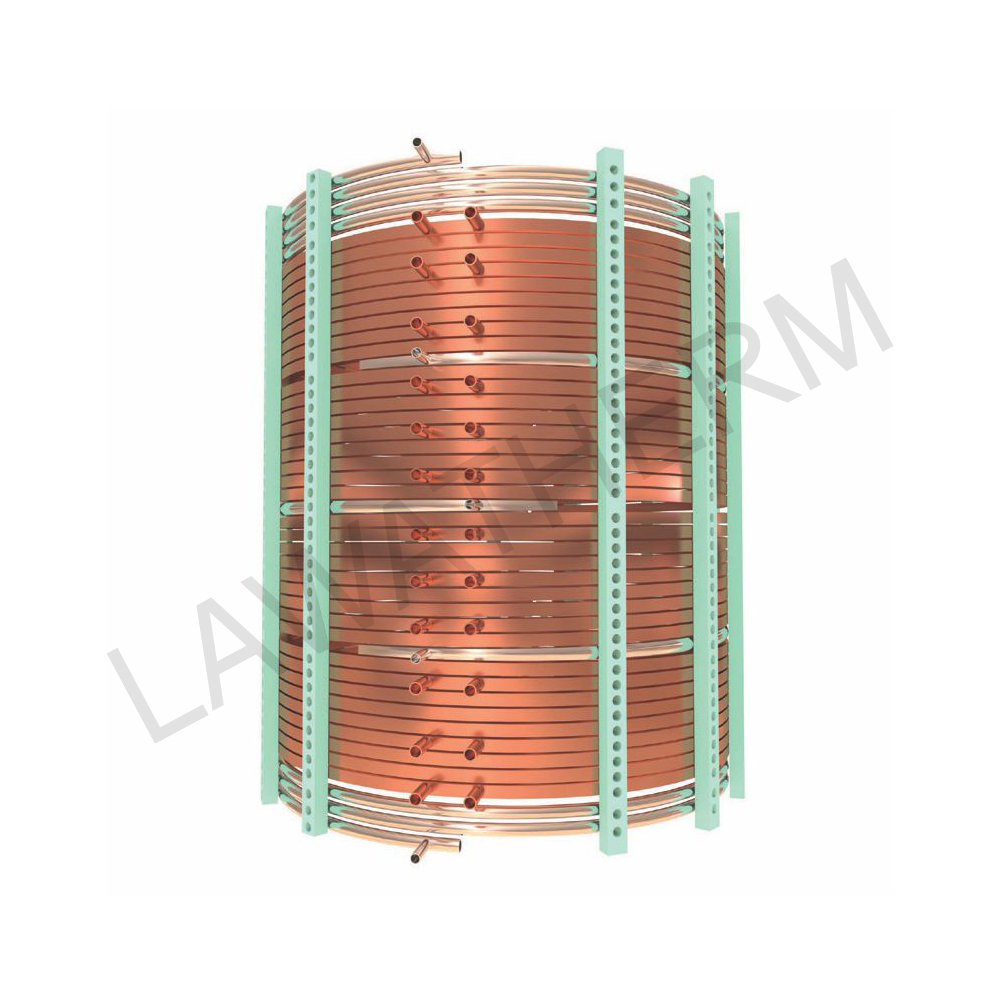

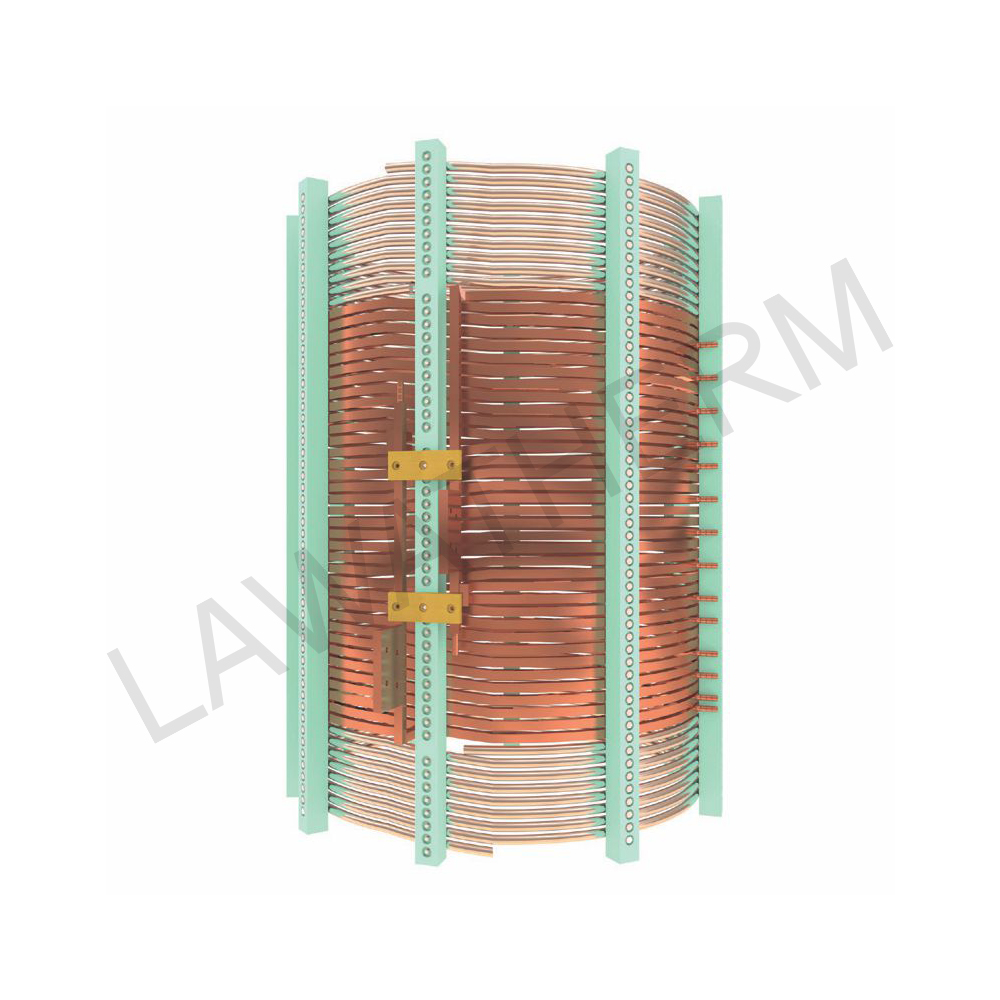

induction Furnance Coil

Coil of an induction furnace is considered its main part. The main function of the coil is to create magnetic fields required to conduct eddy currents

that leads to heating or melting scrap metals or processed ores. Taking into account the role and importance of this part, the electrical and mechanical properties of coil remarkably affects the function and efficiency of the furnace. Therefore, considering diversity of material and quality of parts used for manufacturing coils,Lawatherm provides a wide range of coil design for the induction furnace, whether designed in the company or as the drawings of t he original coil provided by the costumers (in case an spare part is being provided). So, customer will be able to choose design, used material and even properties of the insulation on the intended basis.

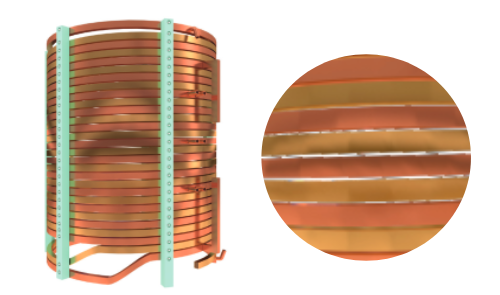

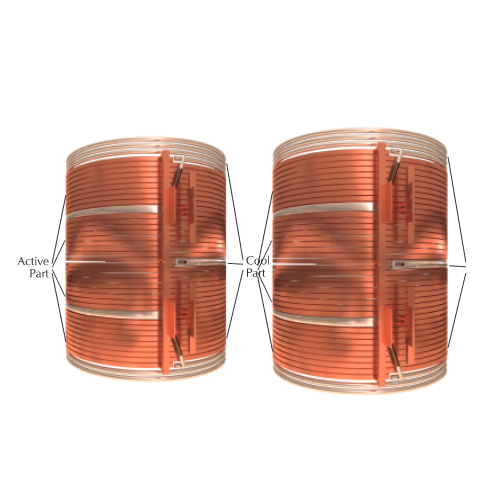

A schematic view of conventional designs of coils manufactured by Lawatherm for its costumers all across the world are as follows:

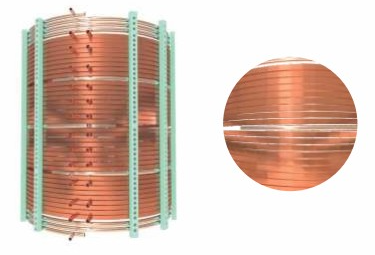

HELICAL COIL

Mostly designed using a number of contrary coils assembled to gether, Helical Coils, winded as spirals, are the most conventional ones practically. The main flaw for this design is the significant gap created between different parts of the coil including contrary active parts of the coil and neutral cooling parts. Being unable to provide smooth edges and adjust height of the coil precisely and finally im balance of magnetic field produced by the coil are the other dis advantages. Most of coils manufactured by Chinese companies and some Turkish factories are placed in this category

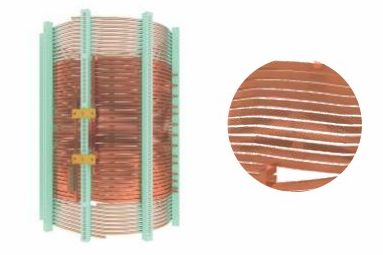

OFFSET COIL

The design of these coil are similar to the helical ones but with a small difference based on the idea of creating an offset in each 360-degree rotation of loops; so, each layer almost comes to a flat, horizontal condition except the offset area. Therefore the design doesn’t have the problems mentioned for the helical coils. Taking into account the physical condi-tions of coil, there is no airspace between different parts of the coil; the upper and lower parts of the coil are created as flat and parallel to enable manufacturer and user to adjust height of the coil precisely. Because of the perfect balance between loops of the coil, the magnetic field produced by coil is more harmonious in different parts inside it. Most of coils manufactured by Indian companies like Electroterm and Megatherm and also some coils made by American companies like Ajax are places in this category. It is recommended using this kind of coils in high power and high capacity furnaces.

DESIGN

The precise design of a coil, electrically and mechanically, using software and computer simulation is the first step of manufacturing a coil. This step is important not only for coils designed in the company, but also for ones manufactured on the basis of drawings provided by the costumers. Finally, according to the simulations and the results conducted, the necessary drawings and a list of required material is being executed and sent to the production department to begin the production.

DUAL TURNS COIL

The main feature of this design is merging the two active parts of the coil together and inside each other. Generally the two active coils lo-cated at the centre are designed as spirals (like helical coils) while the upper and lower parts that are neutral cooling coils are winded as off-set coil. Advantages of this kind of coil are high functional efficiency and more suitable water circulation. Most of coils manufactured by German Companies and some Turkish companies are placed in this category.

RECTANGULAR COIL

Winded in a rectangular section, a rectangular coil is mainly used in channel furnaces and sometimes in the preheating furnaces. The size of these models are generally smaller than the above-mentioned coils. This kind of coil is manufactured and used is two forms: Helical and Bended straight

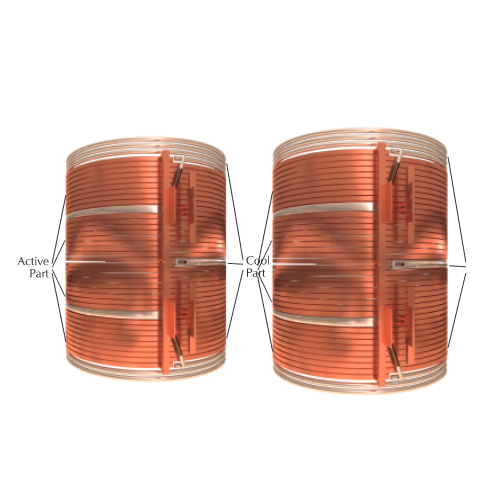

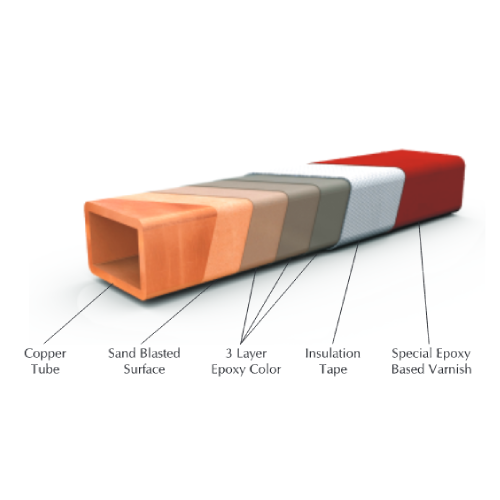

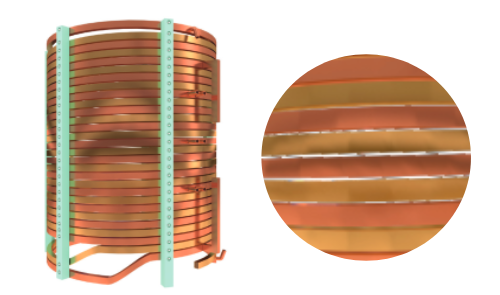

ACTIVE PART

The active part of a coil is in charge of creating magnetic field required to run the melting or heating process and is composed of layers of copper tubes. There are three very important points about the copper tubes:

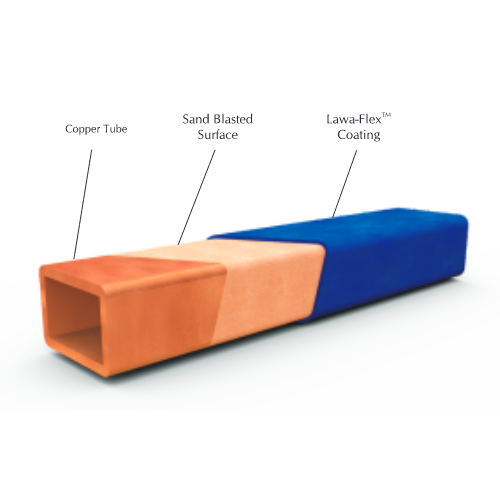

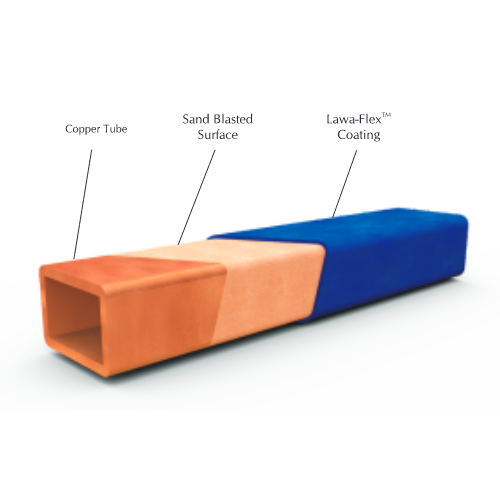

INDUCTION FURNANCE COIL METHOD 1

Lawatherm has invented a special insulator for insulating coils made by the company, named Lawa-Flex, as its brand. The most important property of this special insulator, which is an electrostatic powder dye based on epoxy, is that it doesn’t crack or separate from the coil’s surface in case of intense expansion and contraction of conductors of the coil during application. High thermal endurance, high insulation strength and uniform adhesion specification while applying with a special instrument are other properties of this special insulator. This insulator is applied TM solely, without using other auxiliary materials; no need to use other insulators like liquid ones and insulator tapes in addition to Lawa-Flex in case of using the coil in standard conditions. Taking into account that it is possible for Lawatherm to apply the said insulator, the coils manufactured may be insulated using Lawa-Flex2M as Method No.1. It should be noted that coil undergoes a complete sandblast before applying the powder insulator to remove oxide layers from its surface.

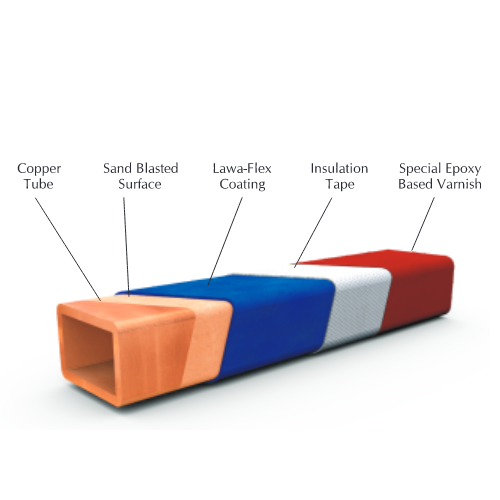

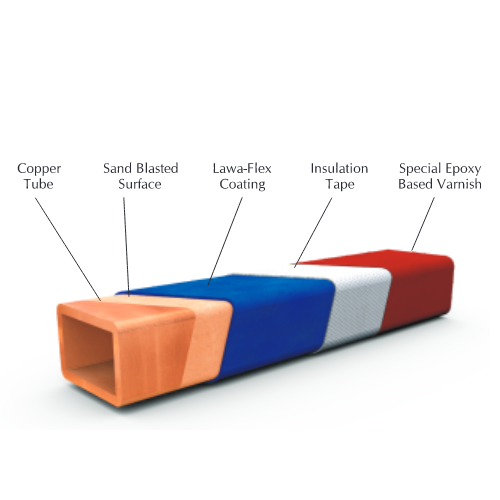

INDUCTION FURNANCE COIL METHOD 2

In method no.2, in addition to primary insulation of coil using Lawa-Flex, a layer insulation tape and a special epoxy liquid are used to improve security margin of application. Using this method is suggested only when the coil is used in a high risk and non-standard conditions; otherwise, in case of using the coil in a proper and standard conditions, Lawa-Flex will be sufficient.

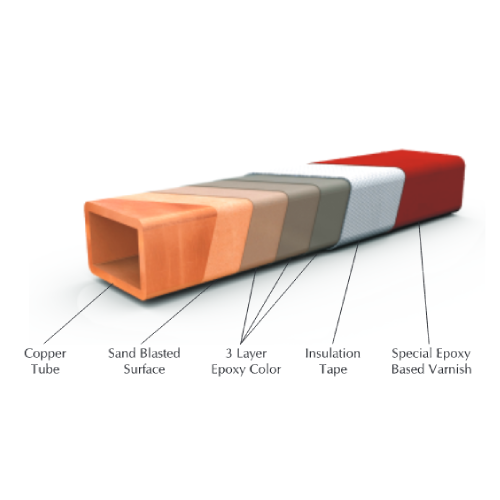

INDUCTION FURNANCE COIL METHOD 3

Using this method, insulation is applied without Lawa-Flex. After a complete sandblast of the coil, its surface is coated using three layers of 1 especial epoxy dye; then, a layer of insulation tapes are winded on it and finally, a layer of special epoxy liquid varnish is sprayed on the surface. This method is used when repaired coils are insulated and miniature leakage is probable.

MATERIAL OF THE COPPER TUBES

The copper used to make sections applied in the active part of a coil should have the maximum purity (at least 99.9%) and con-ductivity (at least 58 mega Siemens per meter); the impure part of the material should contain the least amount of disturbing elements like Phosphorus, Oxygen and Iron that cause intense drop of conductivity, explosion and excessive heating of coil. Thus, taking into account the above-mentioned descriptions, Lawatherm uses the refined copper grade ETP-C11000 and sometimes OFC-C10100 for specific orders, to fulfil all the required conditions

HOLDER BOLTS

Function of holders is connecting support to the body of the coil and include Stainless steel bolts grade 304 or 316, welded to the surface of copper tubes (with or without copper intermediates) or brass bolts which are restrained by flat washer, spring washer and nuts.

INSULATION

Coils manufactured by Lawatherm are always insulated observing all the details; all the points are insulated from each other in a multi-layer way. Since coil insulation prevents coil breakdown and continual stoppage of melting, technical experts of Lawatherm consider this matter during stages of coil manufacturing. Thus, Lawatherm suggests three methods depending on the customer’s requirement.

SHAPE OF SECTIONS

Amongst many properties Shape and cross section of copper tubes affects the coils productivity and long-life the most. In addition to this fact that the effective area of the section must be enough to carry the enormous current conducted through the coil, geometric shape of the section is very important and is not generally considered as it deserves. Geometric shape of the section should provide enough space for current flow of the coil considering two points: Firstly, depth of magnetic field pen-etration inside the section (which depends completely on fre-quency); secondly, quality of cooling and water flow through the conductors. Generally, blockage, sedimentation and corrosion of the copper is expected to happen at sections with sharp corners on the inside (water channel), especially if quality of coil water is not suitable. So, it is recommended using sections with curved corners while manufacturing active part of a coil, to prevent the above mentioned matter.

SLIVER BRAZING ROD & FLUX

_Lawatherm offers these alloys in a wide range of compositions to suit specific applications in the field of maintenance & repair for water pipes (cold & hot water) in copper busbar and squirrel cage rotors.

_Silver brazing produces joints that meets specifications which provides excellent flow characteristic, electrical conductivity, pressure tightness, corrosion resistance and service temperature ,metal joining operations often employ silver brazing.

COOLING PART

The main function of cooling parts of a coil is to cool down the upper and lower sections of

the coil which carry no currents. Cooling parts are generally made by pipes or rectangular

tubes made of stainless steel grade 316 or sometimes like active part of the coil, using

copper tubes

COIL SUPPORT

The main function of coil supports is to keep the gap between the layers and keeping diameter of the coil fixed during the time.

They are made of composite insulators. Specifications of an ideal support are as follows:

- High electrical resistance to ensure isolation between loops

- High tensile and flexural strength to endure electromechanical forces

- Ability to absorb minimal moisture to stabilize mechanical and electrical properties during time

- Thermal endurance in proper limitations.

The following table shows a comparison between grades used in quality of supports.

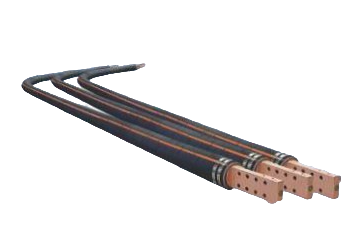

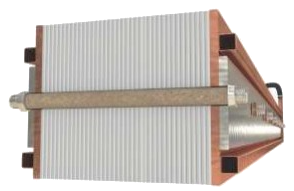

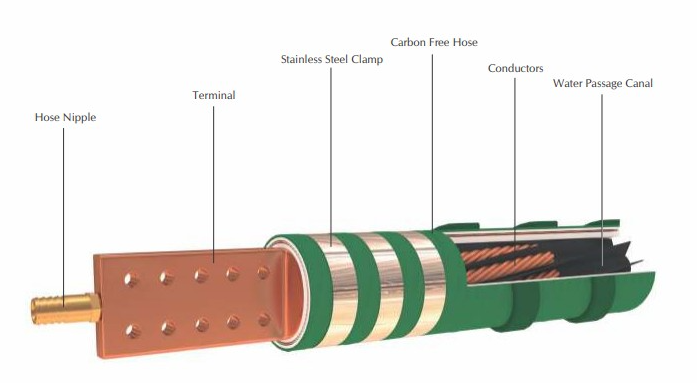

WATER-COOLED POWER LEADS

Water cooling is one of the most important factors of induction equipment; more than 90% of the problems with melt systems involve water. Most of this boils down to overheated coils, due to restricted water flow in the power leads. Lawatherm has in-house capabilities to make, rebuild or recover all makes and types, as well as to customize a cable for a specific need or application. It is highly flexible together with adequate toughness to help passing the electrical cable assembly through the hose. Copper—rated at 101% electrical conductivity by the IACS and soldered to the terminal to insure optimum contact and conductivity is used. This cable is covered with a non-conductive hose constructed of a nitrile tube, multi-ply reinforced center and a neoprene cover that protects your cable against damage from heated material, with a 1000-psi minimum burst pressure and a continuous operating pressure of 250 psi. Flange-type terminals are resurfaced and silver plated for optimum contact and electrical conductivity. These are carbon free hose offering an extremely long life through their characteristics of abrasion and weather resistance. They are specially designed and manufactured to take the abuse in the toughest of working environments. These kinds of hoses are mainly used for carrying power cables in electrical induction furnaces, servicing in iron & steel industries for protection from exposure to high temperature, current leakage and radiation from steel furnace, open flame and splashes of hot metal.

WATER COOLED CABLES

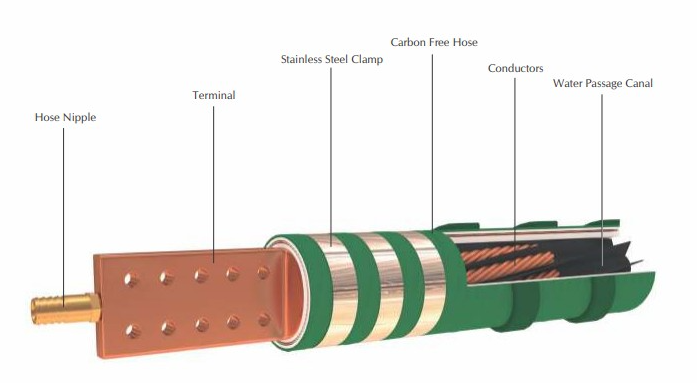

Water Cooled Cables transfer electrical power from power source to the crucible of furnace. The power flows through conductors in the cable and the heat created by the high current is removed by the water flow through the cable. Water Cooled Cables include a wide range of models with different material and designs which are used considering electric current running them and type of usage. Lawatherm designs and manufactures different types of Water Cooled Cables using its experimental and technical knowledge and also qualified material. The Water Cooled Cables manufactured in this company are categorized in three main groups:

CONDUCTORS

Conductors used in Water Cooled Cables are composed of twisted copper wire strings which are mostly bare and sometimes tin plated (mostly in secondary cables). The copper used for these wire strings is completely softened (annealed) ETP grade Copper (According to ASTM C11000). Water Cooled Cables are divided into two groups regarding arrangement of conductors inside the cable: “Continuous” and “Separated”. In continuous Types, conductors of the cables are composed of thin strings in high numbers (with little number of wires); while, the separate cables are composed of conductors with wires in lower numbers which are thicker (or the number of strings is more) compared with the continuous ones. The twist angle of single strings in two adjacent layers are symmetrical.

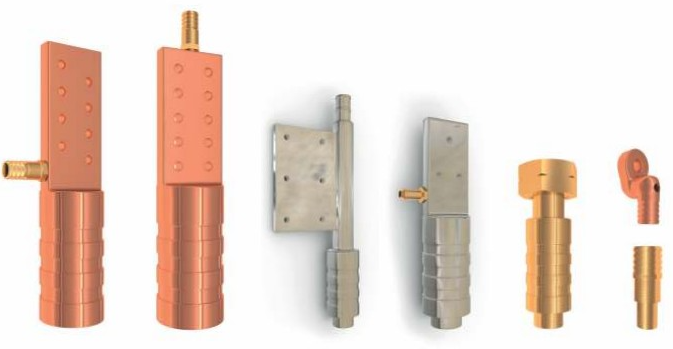

TERMINAL

Cable Heads used for manufacturing Water Cooled Cables are produced as designed in the R&D or according to the drawings provided by customers. Cable heads are generally produced as one-piece through forging and machining copper billets. Sometimes they are as multi-piece through welding machined parts which is not advised especially in high-power cables. Material of the copper used is “ETP grade copper” (according to ASTM C11000) in a softened (annealed) way. The following figure shows some of the convenient terminals (cable heads) used for manufacturing Water Cooled Cables.

WATER PASSAGE

Water Passage Canals are used by water flow to pass through the Water Cooled Cable; otherwise, water flow will b stopped because of ravels of conductors in the cable. These canals are generally used in the average-power cables and the high-power ones; using them in the low-power ones (Secondary Cables) is not necessary.

The said canals are used in two ways:

- Spring type: spring formed, made of stainless steel grade 304 or copper;

- One-piece: have a circle (tube) or polygonal cross section, made of extruded plastic, resistant to corrosion.

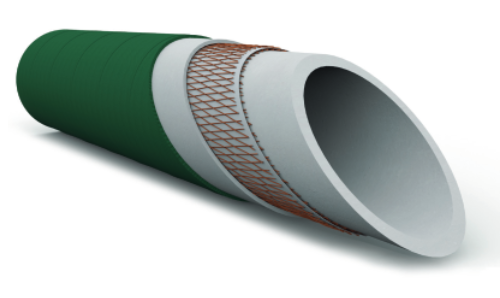

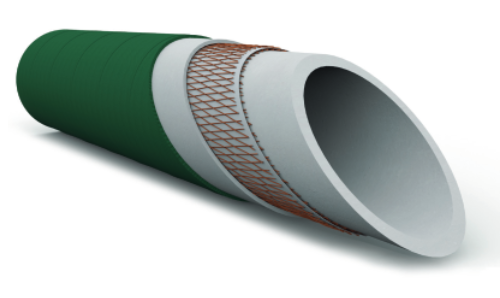

HOSE

Hoses used for Water Cooled Cables are made of carbon-free materials and are resistant to corrosion; they are strengthened by woven synthetic fibers in one or two layers to prevent from tearing. Also, the outer surface of hoses is protected using a layer of fireproof material. The maximum working pressure for Water Cooled Cables is 10 to 20 bars in case of continuous usage; the maximum tolerable pressure for them (tearing limit) is about 40 to 50 bars.

Fire-Proof Protective layer for protect hose from melted particle made by 3 Glass fibers or NBR

Reinforcement layer to prevent hose from rupture made by glass, cotton or synthetic fibers

Inner & middle layer of hose made by carbon free, anti ware, anti corrosion & electric insulator 1 2 rubber from EPDM , XLPE

- Ethylene Propylene Diene Monomer (M-Glass)

- Cross- Linked Polyethylene

- Nitrile Butadiene Rubber

HOSE CLAMPS

The fasteners used for sealing hose of a Water-Cooled cable are made of stainless steel to prevent from heating under magnetic field around the furnace. They are used as disposable and toothless to make sure that they won’t be opened during the time

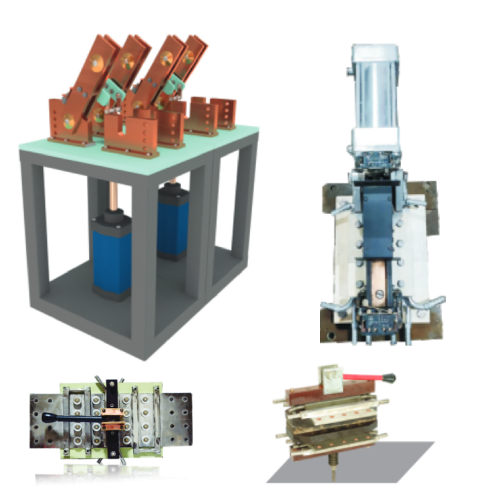

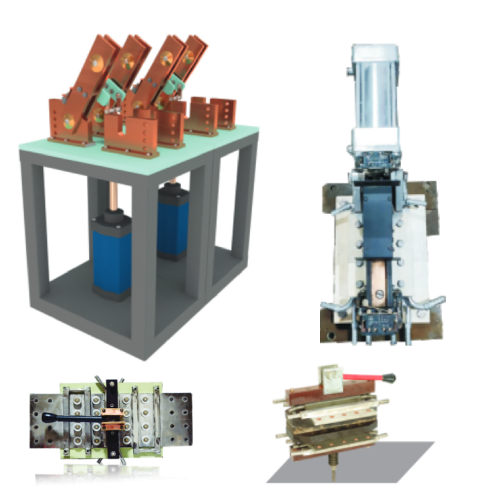

CHANGEOVER SWITCH

Changeover Switch is a tool to change the crucible connected to the feeder. These switches are categorized in different types regarding number

of input and output; they are introduced based on number of feeders of the furnace and also their crucibles. Generally, number of feeders of an

induction furnace is one or two and number of crucibles connected to feeders is two or three. The most convenient type used in changeover

switches have one input and two outputs.

Changeover switches are divided into three groups regard ing function mechanism: manual, electrical and pneumatic.

- Manual : In this group, changing the crucible is applied using a lever connected to the switch manually.

- Electrical : in this group, changing the crucible is applied using electromotor power.

- Pneumatic : pneumatic changeover switches change crucible from the feeder using pneumatic cylinders. This group is the most convenient ones used in steel industry.

A schematic view of pneumatic changeover switches with one input and two outputs which are manufactured by Lawatherm is as follows:

CHANGE OVER SWITCH

The Lawa change-Over Switch is manufactured from high conductivity copper, silver plated. Lawa Change-Over Switch have a double knife contact system, with heavy contact pressure ensure high performance, excellent self cleaning. High short circuit resistance contact are having double breaking and big isolating distances. This ensure excellent and consistent switching performance.

FLOW SWITCH

The Lawa make indicating type, magnetically actuated flow switches are designed for positive detection of fluid flow through your equipment. Flow range covered is from 1 to 150 LPM. Fluid Flow in the System is seen through transparent tube. The clearance between the float and inner surface of the transparent tube are large enough to let floating particles to pass through, eliminating the chances of clogging. This also reduces the pressure drop across the switch. All switches are strong and lightweight. Adequate magnetic shielding is provided as an in-built feature, enabling the user to mount the switch in any location.

PRESSURE GAUGE / PRESSURE SWITCH

Our product is very safely and efficiently designed under the supervision of our highly diligent and hardworking man force such that it is structured to facilitate ensure safe, trouble-free performance. These are known or their brilliant functioning, quality material compatibility, adequate ratings, proper installation, easy operation and maintenance. Our product range includes Vacuum Gauges, Level Gauges and Liquid Level Gauges etc. Our sole aim is to put a smile of contentment on the faces of our customers and do our best in making that possible.

HOSE CLAMPS

The Lawa stainless Steel Hose Clamps are engineered to meet the exact requirements for our client and within the specify time frame. Our Clamps like heavy duty strip Clamps, Wire Clamps, Worm drive Clamp, have created a strong market presences due to their superior strength excellent gripping and availability in a wide range of designs

INSULATION SPARES & MATERIALS

INSULATION

Insulation is the reduction of heat transfer between objects in thermal contact or in range of radiative influence. Insulation can be achieved with specially engineered methods or processes, as well as with suitable object shapes and materials. Lawatherm, is a leading edge manufacturer of insulation products which offers high inherent dielectric strength, mechanical toughness, flexibility and resilience and is widely used in a majority of electrical equipment applications. Our steel Industry products and services help ensure safety, enable lighter designs and reduce maintenance costs of equipment – especially for melting furnace.

Lawatherm technology helps develop that utilized energy more efficiently, require low maintenance, with zero compromise on safety and long-term performance and we continue to innovate. Whether you are in the oil and gas, automotive, chemical, agricultural, food processing, manufacturing, or maintenance businesses, there’s an industry – leading Lawatherm material suited to the job you need to get done. Lawatherm has readily available in-depth stocks of a wide range of insulation products including some of the best brands i.e. Lebond, Dupont, Dr.Beck, Thermosil, Arco, Champion, Charminar etc.

FLEXOCOAT 2216 BASE / HARDENER

Lawatherm is a specially designed durable, high dielectric insulating material, which replaces old style epoxies, polyster and varnishes insulation systems. Application of these materials is crucial. This is why special heating equipment to properly cure the insulation is required with these materials. Utmost care should be given to apply the material to provide uniformity of application.

Maximum precaution is taken to insure that the first layer of insulation is applied to the accurate amount of thickness and properly cured before the second coat is applied. If the first coating is too thick or not properly cured, “outgassing” can occur, causing turn to turn arcing and premature failure of the coil. Special high-voltage electrical tests are carried out on the entire coil to insure the integrity of the insulation. Lebond 2216 has been heated to 450°F and subjected to high voltage non-destructive tests [up to 6000 Volts DC] with no indication of failure. Flexocoat lebond 2216 for coating induction coils of electric induction furnace, it has excellent adhesion on copper and stainless steel desired flexibility to withstand cooling and heating cycles normally encountered during operation of furnaces and provides electrical resistance to voltage developed between the coils to protect from sparking, upto approximately 400 volts / mill. Thickness of coating.

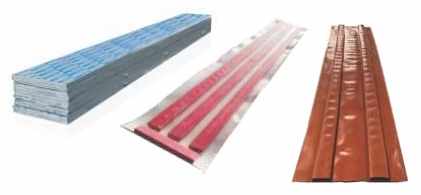

FRP (FIRE RETARDANT PROOF) RODUCTS

Lawatherm manufactures Fiberglass products (Epoxy and Polyester) in various sizes and shapes of Sheet, Flats (coil Support/Bar), Rods, Tubes, Spacer, Angles & sections. These sections being made from epoxy resin and glass fibers combined together give an excellent performance that combine high strength and excellent electrical insulating characteristics for use in a variety of applications where electrical insulation and non- corrosive material is required in the electrical and thermal insulation industry. The company believes in ‘providing satisfactory solutions and assistance’ to the clients. With zeal to achieve consistent growth, the company strives on customer satisfaction as its main motto. A variety of custom built sections can also be made upon demand of the customer.

GRADES

G-10 and G-11 (Glass Cloth / Epoxy Resin) This glass epoxy laminates are specified for their extremely high stability over temperature, G-10 and G-11 are used for terminal Board, insulation in electro magnet separators, High humidity

applications, LV and HV circuit breakers, Electric Rotor Insulations, and where strength to size ratio is critical, G-10 is stronger while G-11 is a better insulator and can take higher temperature.

FR-4 (Glass Cloth / Epoxy Resin).

FR-4 is Fire Retardant G-10 Glass Epoxy laminates.

INSULATION PAD

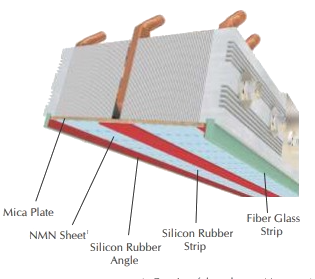

Insulation pad is a set of insulating layers placed between the coil and the yokes of an induction furnace which are used to isolate them. Lawatherm provides insulation pads in different types with special properties and applications. The following images show compositions and layers of provided insulation pads by this company.

SPACER

Using insulation materials in all the electrical parts of an induction furnace is very important and inevitable. Any small insulation defect may lead to an error or a short circuit, and thus an stoppage of melting process in a furnace. Spacers should be necessarily applied between loops of a coil. Spacers strengthen the coil’s coating in addition to reinforcing insulation power in the space between loops of a coil. Spacers are divided into groups regarding their material: Mica and Fiberglass; They are also divided into two groups regarding their form: lunate spacers and wedge spacer. Lunate spacers are used in a continuous mode and the wedge ones are used in an interrupted mode.

• Mica spacers have more thermal capacity compared with the fiberglass ones and instead, they cost more.

• lunate spacers provide more electrical and mechanical strength compared with the wedge ones.

• The continuous lunate spacers are produced through machining and overlaying with a certain overlap. (0 to 50 percent overlap) More overlap means more strength and so, more assurance. Instead, in this case moisture outlet will be more difficult during sintering.

REFRACTORY BLOCKS

Refractory blocks are installed between the coil and the structure, at the upper and lower sections, as isolator. They are manufactured by moulding Alumina (50 percent purity and having fibers) in the desired form and dimension. Metallic non-magnetic material is used during moulding to reinforce concrete and prevent from fragility. Refractory blocks are used in “One-piece” or “Multi-piece” way. The advantage of using multi-piece types is to provide space between blocks to prevent their cracking because of expansion as a result of furnace heat

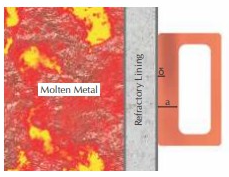

ISOLATOR BETWEEN THE REFRACTORY AND THE COIL GROUT

This isolator is used behind the refractory lining of induction furnaces to isolate coil grout from the refractory materials. These isolators prevent the leakage of the melt to penetrate the coil grout. In addition, a specific type of these isolators is used as a part of melt leakage warning system and are generally produced and used as a roll of flexible mica based material in different grades. A table on the next page shows different grades of rolls which can be used and provided by Lawatherm.

In case of using the material which is mentioned at No. 2 of the table, melt leakage warning system that is suitable with this material, may be used. To achieve this, at first, the required modifications should be applied to furnace system and then, a special resistance measuring instrument that is being provided by Lawatherm should be installed to measure and monitor momentary resistance between middle layer of the isolator (nonmagnetic SS layer) and the earth neutral (that is already connected to melting by antenna). This way, in case of gradual leakage of the melt and its approach to the isolator layer, the measured resistance gradually reduces and in case of dropping more than the amount defined before, the installed system warns and even sends trip order in case of emergency. This method is one of the effective and cheap methods for melt leakage warning system in a furnace.

MICA PRODUCT

Lawatherm manufactures Mica products in various sizes and shapes of Sheet, Rods, Tubes, Tapes(PSA), Spacer, Half round mica turn & also lifting magnet insulation spares.

Composition

It consists of several layers of muscovite mica paper

impregnated with silicone binder pressed under heat &

pressure to yield plate / board having excellent mechanical,

thermal and electrical properties.

Application

- Insulation of high temperature heated platens and moulds in hydraulic and presses

- High temperature insulation of electrode arm in arc furnaces and ladle furnaces

- High temperature insulation between coil and crucible in induction furnaces

- Insulation in dynamic braking resistors used in lacomotives

- Applications requiring high voltage resistance at high temperatures

ASBESTOS MILL BOARD

This is a versatile, thermal insulation and heat-resistant material produced in sheet form using good quality asbestos fibres, incombustible fillers and vegetable binders. It does not suffer loss of strength upto 485°C. When suitably supported the board can be used satisfactorily at extreme temperatures upto approx. 1400°C. Service.

For all kinds of thermal insulations ranging from domestic cookers and ironing boards to industrial applications such as glass moulding, ovens and furnaces and domestic stoves. As the sheets can be bent to any diameter with a little moisture, they are most suitable for large diameter pipe cladding.

TEFLON SHEET

Lawatherm is one stop shop for electrical insulating materials and composites of Engineering Plastic Products. The Teflon (PTFE resin skived)sheet are highly dielectric, chemical resistant and not ageing. They have a wide range of operation temperature range between -260°C to 260 °C. Over a scientific study done a vast range of component which have excellent property of flouro based which show excellent mechanical behavior like hardness, longitudinal strength, mechanical strength and specially chemically inert for both type of reaction whether acidic or basic. Teflon (PTFE resin skived)sheet are available in continuous rolls or cut to the desired length. Composite materials in the form of Sheets, Boards, Hollow Pipes, Solid Geometrical Profile are used for making fabricated parts as per customer requirements. These process may involve Cutting, Turning, Sawing, Shearing, Punching, Dowelling, Chamfering, Thickessing, Scarfing, Drilling, Shaping, Routing, Scoring, Milling, Grinding, Tapping, Threading Pasting finishing packing etc. all operation being performed by skilled person with advance technology machines. A detailed quality check from procurement of raw material to in process and then at final product level is done to ensure fitment to use as per customer expectation. Available machined components matched to exact specification / drawings.

PARMALI (DENSIFIED LAMINATED) WOOD PRODUCTS

Lawatherm is one stop shop for electrical insulating materials and composites of Parmali wood. The Parmali (Densified Laminated) wood boards for insulation application such as coil-clamping rings, pressure / potential rings, coil supports, spacers, and lead supports etc. Our materials possess extra high voltage insulating characteristics and are used in EHV transformers, large electrical machines, hydro and turbo generators, High voltage switchgears etc. Composite materials in the form of Sheets, Boards, Hollow Pipes, Solid Geometrical Profile are used for making fabricated parts as per customer requirements. These process may involve Cutting, Turning, Sawing, Shearing, Punching, Dowelling, Chamfering, Thickessing, Scarfing, Drilling, Shaping, Routing, Scoring, Milling, Grinding, Tapping, Threading Pasting finishing packing etc. all operation being performed by skilled person with advance technology machines. A detailed quality check from procurement of raw material to in-process and then at final product level is done to ensure fitment to use as per customer expectation. Available machined components matched to exact specification/ drawings.

SINDHANIO PRODUCT

Lawatherm is manufacturing syndino products in various size and shapes of sheet, rod, spacer, segment, half round syndino turn, top & bottom. These sheets are available in various sizes from 2mm to 75mm.

Composition

Lawatherm consist of asbestos fiber and cement formed into fully compressed boards under high pressure, mechanically strong, these boards possess good arc and heat resisting characteristics are used for thermal insulation as well as electrical insulation.

Application

- Insulation of high temperature heated platens and moulds in hydraulic and presses

- High temperature insulation of electrode arm in arc furnaces and ladle furnaces

- High temperature insulation between coil and crucible in induction furnaces

- Insulation in dynamic braking resistors used in locomotives

- Applications requiring high voltage resistance at high temperatures

NOMEX PAPER

Nomex paper is an insulation paper which offers high inherent dielectric strength, mechanical toughness, flexibility and resilience. Nomex paper is the original form of Nomex paper, and is widely used in a majority of electrical equipment application. Available in 11 thicknesses (0.05 to 0.76mm) (2 to 30mil), Nomex paper is used in almost every known electrical sheet insulation application.

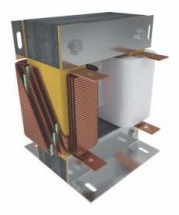

Reactor (Choke)

REACTOR (CHOKE)

Reactor is an inductor to be used in electrical circuits in two ways: series or parallel, including AC or DC to fulfil the following aims: a)to supply fixed current sources b)to confront sudden Current alterations and etc. In furnace industries, reactors are installed in AC and DC power circuits of furnaces.

AC REACTOR

AC reactors are not necessarily used in power circuit of induction furnaces. The initial design conditions makes them applicable for electrical system of a furnace. In case of using them in an induction furnace, they should be single phase. They are installed in parallel way to the capacitor bank of a furnace to discharge energy of the capacitor in case of need and complete the resonant circuit of the furnace.

DC REACTOR (DC LINK)

In fact DC link connects the rectifier and the inverter. Their function is creating a DC current source to feed the furnace inverter. DC reactors are manufactured in a given inductance and power and installed in the furnace system. Meanwhile, Lawatherm manufactures new reactors according to the drawings of the customers to fulfil their requirements and also, recommends its own models as a result of combining and improving different structures.

The most important parameter of DC reactors is their inductance. It is recommended to manufacture the reactor in multiple taps to make them compatible with other sections of the furnace; they should be used in a tap appropriate to other parameters of the furnace. Naturally, the used tap will change in case of changing parameters of furnace.

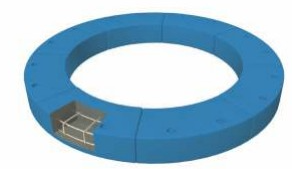

Induction Furnace Yoke

MAGNETIC YOKES (SHUNTS) OF INDUCTION FURNACE

Magnetic Yokes of Induction Furnace collect and conduct the magnetic field produced by the coil. The better the material used in the core the higher the furnace efficiency and lower the thermal losses. Also, quality and geometric structure of the yoke affects uniformity of magnetic flux dispersion inside the furnace, turbulence created by the field and quality of melting. Lawatherm manufactures different kinds of magnetic yokes according to the drawing or designs provided by customers or according to its own design based on the application conditions of the customers, using cutting-edge technology and its experienced staff.

A schematic view of convenient models of yokes used in the induction furnaces is as follow:

The main parts of a yoke which should be considered while design, are: core, cooling system, assembly and connector. Properties and specifications of each element are as follows:

CORE

The core of a magnetic yoke is composed of magnetic sheets of various materials. Quality and thickness of the used sheets affects magnetic permeability and flux integration, amount of energy losses and as a result, furnace efficiency. Main Factors affecting the said matters are briefly as follows:

- Thickness of the sheets

- Amount of silicon in the Material

- Dispersion of silicon grains along the sheet

- Magnetic saturation point

The above mentioned factors lead to loss reduction in mass unit, effective life time and magnetic flux capacity. The following table shows acomparison between grades of the used sheets in the core of magnetic yokes produced by Lawatherm.

The main parts of a yoke which should be considered while design, are: core, cooling system, assembly and connector. Properties and specifications of each element are as follows:

1. Cold Rolled Grain Oriented

2. High permeability cores including: MOH, Laser, …

3. Cold Rolled Non-Grain Oriented

4. The least guaranteed density of magnetic field which leads to core saturation; this amount is estimated at 800 (A/m) magnetic field intensity for CRGO and Hi-B core sheets and 2500 (A/m) for CRNGO

YOKE BASE

Base of the yoke means the way yoke sites on the side of the coil. The base may be flat or curvature. Curvature based Yokes provide better mechanical stability compared with the flat based ones. Also, curvature based yokes prevent attraction of dust to the space between yoke and the coil and reduce probability of short circuit between them. Instead, flat based yokes provide better conditions for discharging vapour produced by sintering the refractory lining, compared with the curvature-based ones.

To attain the advantages for both “flat-based” and “curvature based ”models Lawatherm is providing special insulation pads on its newly invented yokes (full-bolted with copper cooling and aluminium holders). By using this special insulation pads with the yokes you can have the option for discharging sintering vapour while retaining mechanical stability of the yoke and prevent penetration of the dust to the space between the yoke and the coil

It should be mentioned that considering excessive complexity of manufacturing curvature full-Bolted yokes, all the manufacturers across the world produce the flat bolted models. While, Lawatherm is able to manufacture all the models of yokes including full-welded, full-bolted and welded-bolted models in two forms of flat and curvature, using its invented technology.

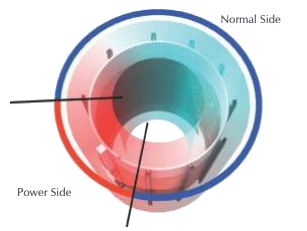

COOLING SYSTEM

The main function of cooling system is thermal exchange and cooling down the yoke’s core which is heated because of magnetic field flow. Design of the Cooling system is based on water flow through lateral and middle cooling sections of the yoke and the number and places of cooling sections in each yoke is determined by the furnace power, number and place of yokes and water feeding system of the furnace.

Considering density of magnetic field around the coil, this region is divided into two parts:

- Power-Side: space around the coil I/O which magnetic field has higher density because of the magnetic field created by the water cooled cables.

- None-Power Side: the remaining space around the coil which magnetic field’s density is less than Power-Side.

Obviously the cooling system used for “Power-Side” yokes should be more effective because of stronger magnetic field. This matter is generally achieved by adding middle cooling sections to the yoke and sometimes by changing material used for making cooling sections

ASSEMBLY OF THE YOKE

The various parts of the magnetic yokes may be assembled together in two ways: through “Bolting” or through “Welding”. The major advantage of bolted yokes is that they can be dissembled in case of breaking down and defected parts can be replaced. Also, the bolted yokes have less Foucault losses than welded types because of not using welding for connecting sheets of the core together and to the body.

The other problem that is encountered in full-welded yokes is the lower part of the yoke being dissipated and opened up that leads to distance between sheets of the core. In the other words because the connection between all the parts is only on the surface of the yoke, the lower part of the yoke that places next to the coil begins to dissipate and open up because of the tension shifted from the welded points on the surface and the pressure of the structure bolts. This opening and the distance between sheets of the core causes intense sounds during application and worse, swarf and dust are attracted to the space between sheets of the yoke. These dust later can cause short circuit at the furnace.

CONNECTOR OF THE YOKE

In fact, connector of the yoke is the mediator between yoke’s body and the structure bolts which fix the yokes at their place; it is designed and built according to the furnace cradle and installed on the yoke in the ways suggested by Lawatherm. Some convenient models of yoke connectors manufactured in this company, are provided. These models are categorized in two main types regarding their application: “Push” models and “Push-Pull” models. The “Push” model connectors are used only for applying pressure on yoke to attach it to the coil; whereas, “Push-Pull” connectors are used for separating yoke from the coil in case of need, in addition to attaching it to the coil.

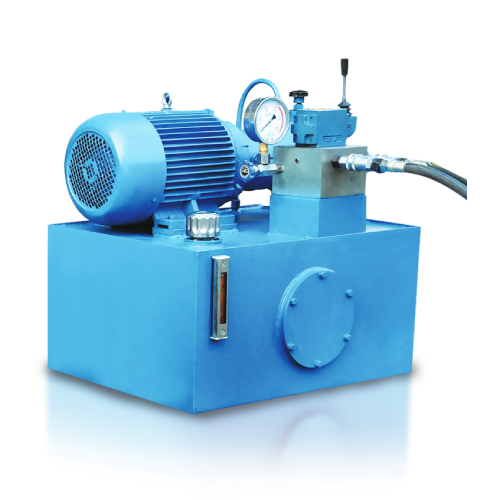

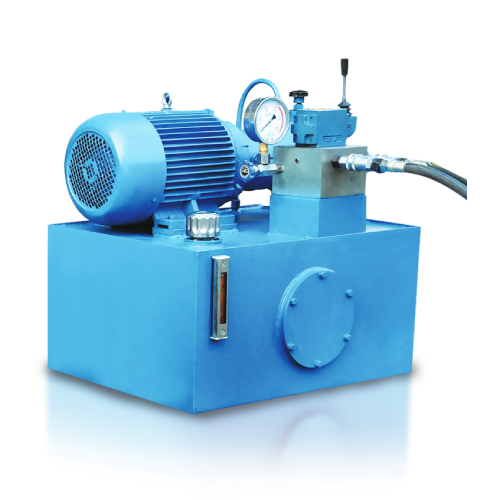

HYDRAULIC SPARE

HYDRAULIC POWER

Lawatherm is one of the renowned suppliers of Hydraulic & Pneumatic Spares. We Provide Hydraulic Pump, Valve, Seal, Pipe, Cylinders, Power Pack, Automation Equipment and SPM.

Lawatherm holds in-depth stocks of a wide range of Hydraulic products including some of the best brands i.e. Dowty, Yuken, Polyhydron, Jacktech, Suprimo, Rexroth, Vickers, Bosch are available with us in ready stock. We will give you the import substitute also in very competitive price.

We have a wide variety of Hydraulic Equipment, which have become benchmarks in the industry. Our quality controllers strictly check the range as per the standard quality parameters. We want to make sure that we can offer our clients highly efficient and durable range of hydraulic spares.

PIPE & V SEAL

Our pipe V seals are available in standard length and other measurements. All of these seals are qualitative in nature and are available in economical prices

GEAR PUMP

Gear pumps (with external teeth) (fixed displacement) are simple and economical pumps. The swept volume or displacement of gear pumps for 3 3 hydraulics will be between about 1 cm (0.001 litre) and 200 cm (0.2 litre). They have the lowest volumetric efficiency (approx 90%) of all three basic pump types (gear, vane and piston pumps). These pumps create pressure through the meshing of the gear teeth, which forces fluid around the gears to pressurize the outlet side. It’s widely used on the industry machinery, mining machinery, loading transportation enterprises and agriculture machines.

DIRECTION / FLOW CONTROL VALVE

DIRECTION / FLOW Control valves can also work with hydraulic actuators (also known as hydraulic pilots). These types of valves are also known as Automatic Control Valves. The hydraulic actuators will respond to changes of pressure or flow and will open / close the valve. Automatic Control Valves do not require an external power source, meaning that the fluid pressure is enough to open and close the valve. Automatic control valves include: pressure reducing valves, flow control valves, back-pressure sustaining valves, altitude valves, and relief valves. An altitude valve controls the level of a tank. The altitude valve will remain open while the tank is not full and it will close when the tanks reaches its maximum level. The opening and closing of the valve requires no external power source (electric, pneumatic, or man power), it is done automatically, hence its name.

HYDRAULIC CYLINDER

Lawatherm take this opportunity to introduce ourselves as manufacturers of Hydraulic power pack, Hydraulic/Pneumatic Cylinders, as per specific requirement of our valuable customers. We also undertake hydraulic system, up grading modifications for increased productivity.

Our manufacturing range of products includes:- Custom Built Hydraulic & Pneumatic Cylinders

BORE DIA : 25MM to 600 MM

STROKE : 6000MM

MATERIAL SPECIFICATION

CYLINDER TUBES : ST 52.3 BK Grade Seamless I mported pre-honed Tubes.

PISTON RODS : HARD CHROME Plated Rods of CK 45 N grade

PISTON : C 45 Steel, Single Piece, Precisely Machined.

GLAND : Precisely machined steel Gland with Gun Metal Bushing.

MOUNTING : Accurately Machined Steel Suitable for Heavy duty Applications.

SEALIING SYSTEM : Importe Seals.

Temperature Instrument & Calibration

MOLTEN METAL TEMPERATURE INDICATOR

Today Lawatherm is a leading manufacturer of Microprocessor temperature measurment as well sensor, expandable thermocouple tips for molten metal temperature indicator both ferrous & non-ferrous & steel plants. We are focused to manufacture & supply best quality temperature measurement instrument related products. We are the pioneer in producing thermocouple tips, carbon cups, recepictal and temperature measuring instruments for molten metal in a wide range as per industry requirement and customer’s specification. We arewell recognized in the industry for our best product offered at the best rate in minimum delivery period.

- Molten metal temperature indicator

- Expandable thermocouple tips

- Temperature Sensor

- Temperature Gauges (Thermometer)

- Temperature Switch (Thermostats)

- Digital Temperature Meter

- IR Temperature Gun

- Cables

- Thermocouple RDT’s

Electric Product

WIRE & SWITCH GEAR

Lawatherm providing innovative solutions for reliable electric power supply products. Lawatherm is ranked amongst the leading importers and distributors of L.T. Switchgears including electrical protection equipments, circuit protection device, electric circuit components, We have been successfully catering to the varying needs of Low Voltage Industrial and Domestic segments of the market. Our team consists of proficient engineer sand technocrats who are not only well versed with the industrial dynamics, but also engaged in research to keep themselves abreast with the technological advances.

We have developed an extensive expertise is customizing the products to meet unique requirements of the Government and Corporate clients Our range of products include AC Contactors / RCCB / MCCB / Push Button Stations / Power Supply / Proximity Sensors / Solenoids / Electromagnetic Relays / Plastic & Metallic Plug & Socket / Heavy Duty Connector / LED / Foot Swicthes / Micro Switch & Limit Switch / Sirens / Tower Light / Thermal Overload Relay. We believe in the continuous policy of research and development to maintain our product range in line with the latest demands of the market. Our products comply with national & international quality standards and passion for continuous quality development keeps us going. Our singular focus is to provide total customer satisfaction with absolute commitment to quality of our products.

AXIAL FLOW FAN

The Lawa Axial Flow Fan has been specially designed for removal of dust and fumes in work places where, due to long ducts, system-resistance is high and other conventional Exhaust Fans will not serve the purpose. This aerodynamically efficient fan is available in diameters from 12” through 42”, with direct drive capacities rangingto 29,000 cfm.

The Lawa Axial Fan housing is constructed of heavy duty welded steel and angle ring flanges, with a spark resistant, cast aluminum airfoil axil impeller.

The basic functions of ventilation and air conditioning are effectively performed by Axial Flow Fan, especially in industrial process system, crop drying, mines, foundries, steel plant, rolling mill, glass plant, power plant and other industrial facilities

Sintering Pre-heater

Lawatherm manufactures state-of-the art Pre-Heaters for furnace and the ladle and supplies its systems across India and abroad. Our pre-heaters are custom designed as per the need of the consumer.

SINTERING PRE-HEATER FOR FURNACE

- Pre-heating the furnace reduces its energy requirement for melting and thus increases the

efficiency of the melting process in sintering heat cycle. - Lawatherm customized sintering pre-heaters for furnace can be used for a capacity of 6-30

Ton, heating the furnace up to 600 degree Celsius within 180 minutes. - The Nichrome strip used as the heating element can sustain high temperature effortlessly.

- Provides safer work environment during melting process. Enhances longevity of the furnace.

- The initial set up cost is significantly low compared to any other pre-heating systems

available in the market. - The process minimises carbon emission and thus helps reducing pollution.

- Pre-Heating the furnace improves the melting rate by maximum 15%.

- Helps increasing productivity significantly.

- Temperature measurement and control is automatedand the pre-heater is fitted with a digital

temperature indicator. - Lawatherm furnace pre-heating systems are flexible and removable. A single per-heater can

be used for different furnaces of similar capacity at the same shop floor.

VARIOUS TYPES OF FURNACE PRE-HEATERS: COLD SINTERING PRE-HEATERS:

• Less preheating time •Moderate soaking time •Cost effective

Hot Sintering pre-heater:

- Moderate pre-heating time •Less sintering time •Possible to go to full power in short time

- Effective for synchronizing melting

SINTERING PRE-HEATER FOR FURNACE

- Ladle is pre-heated to remove moisture from the inner-lining and it betters the lining life.

- Lawatherm sintering pre-heaters come in different sizes and capacities- serving ladles from 6-30 Tons and can be heated up to 450 degree Celsius for heating around 200 minutes.

- It helps reducing the cycle time and thus increases efficiency of the process.

- Our pre-heating system uses Nichrome strip as the heating element, hence easily sustain high temperature.

- The process is smokeless and less polluting.

- The Ladle is covered and there is minimum heat loss. The system is energy efficient and saves cost.

- The set-up is flexible and one set up can be used in more than one ladles (of similar capacity) in the same plant.

- Heating control is automated and the heater is fitted with a digital temperature indicator.

- Ensures safety of the worker.

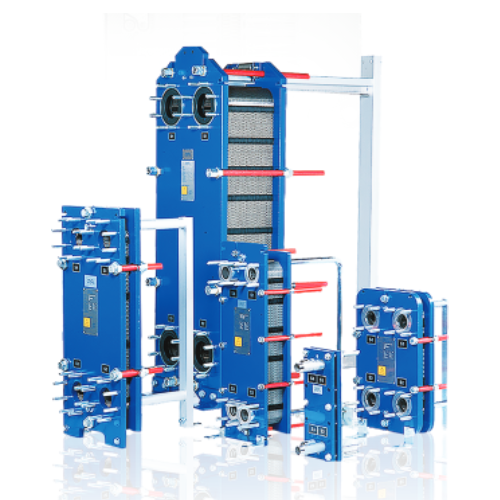

DM WATER CIRCULATION SYSTEM

PLATE HEAT EXCHANGER

Lawatherm specializes in after-market and genuine spare parts for separator equipment (plate heat exchanger) & liquid processing pump (stainless steel centrifuge pump).We are one of the largest and truly independent suppliers of the major OEM’s and after market spare parts and service for Alfa Laval ,GEA Eco-flex, Tranter, HRSheat exchanger, SWEP and others.

In addition Lawatherm is committed to providing the largest selection of spare parts in the industry we also offer a broad range of high quality, genuine gaskets, pump seal, which come with all the same guarantees as their branded counterparts, together with complementary accessories. We are continuously increasing our inventory to meet the demands of our customers . All spare parts whether genuine or equivalent are fully compatible . Lawatherm are able to source and supply spare parts worldwide. Combined with an extensive stock holding, enables us to keep prices competitive and keep lead times to a minimum. We supply a wide range of process components for various applications with in steel melting, food beverage and chemicals processing industries.

“From a seal ring to a complete centrifuge system, Separator Spares Lawatherm can provide solutions for all your separation and spare parts needs.”

HV CAPACITORS BANK

General Information: The active power produced by active current can alone be tuned into an effective use for the consumer, while the reactive

power produced by the reactive current does not yield usable power and consequently is not registered on the active performance meter. The

reactive power has negative effect on the generator, transformer conductor lines, inductive heating and motor chokes while causing voltage drop and

fiscal losses due to additional electric heating. The reactive power required for the creation of the magnetic field round motor, transform continuously

oscillates between current generator and consumers. The more cost effective way to provide the reactive power is to produce is by placing ABB

capacitor close to the consumer of reactive power [Motor/Trasformers].

Thus, relieving the line between generator and consumer of the transport for the reactive portion. This way several more current consumers can be

connected to a existing supply system without having to extend or amplify that system if the capacitor are suitably positioned. Enhancing power

quality improvement of Power Factor saves cost and ensures fast return on investment.

Features

All film dielectric is used and consist of polypropylene in the form of biaxially oriented film, hazy on both sides, and in two or three layers with laser cut aluminum foil for the electrodes. The Capacitors are impregnated with a NON-PCB base fluid. Dielectric Loss approx. 0.1 W/K VAR ABB Capacitors are designed, manufactured and tested to meet the requirements of IS13925-1994,IEC-60871, Voltage Range- 22KV-24KV

Frequency – 50 Hz /60 Hz

Corrosion Protection

Maximum Permissible Current [Capacitors units shall be switched for continuous operation at an RMS current of 1.30 times the current that occurs at

rated sinusoidal voltage and rated frequency, excluding transients].

Temp range: 5°C – 55°C

Decreasing Voltage drop

Application

8Individual PF Correction

individual PF Correction on three phase motor

Individual PF Correction of power Transformers

Individual PF Correction of group power factor correction

Central Power Factor Correction of all industrial /Inductive Loads

Electronic Spares

-

Solid State Generator Panel

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

MF Water Cooled Capacitor

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Semiconductor & HRC Fuse

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

SRC Invertor & Converter Thyristor

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

IGBT Power Module

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Snubber Capacitor

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

WCR High Power Resistor

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Crucible Spares

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

induction Furnance Coil

-

Helical Coil

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Offset Coil

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Dual Turns Coil

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Rectangular Coil

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Active Part

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Induction Furnance Coil

Method 1Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Induction Furnance Coil

Method 2Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Induction Furnance Coil

Method 3Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Cooling Part

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Coil Support

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Water-Cooled Power Leads

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Water Passage

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Hose

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Hose Clamps

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Change Over Switch

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

Insulation Spares & Materials

-

Insulation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Flexocoat 2216 Base/Hardener

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

FRP (Fire Retardant Proof) Products

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Sindhanio Product

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Nomex Paper

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

Hydraulic Spare

-

Insulation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Pipe & V Seal

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Gear Pump

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Direction / Flow Control Valve

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Hydraulic Cylinder

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Sintering Pre-Heater For Furnance

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

DM Water Circulation System

-

Plate Heat Exchanger

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Plate Heat Exchanger

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Plate Heat Exchanger

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

-

Plate Heat Exchanger

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.