Manufacturers & Suppliers of Changeover Switch

Get in touch

Changeover Switch

A Changeover Switch is a crucial component for transitioning the crucible connected to the feeder seamlessly. These switches come in various types, each tailored to accommodate different configurations based on the number of inputs and outputs. Typically, they are designed to suit the number of feeders of an induction furnace and the corresponding crucibles.

The most commontype of changeover switches features one input and two outputs, providing flexibility in operations. These switches operate via three main mechanisms: manual, electrical, and pneumatic:

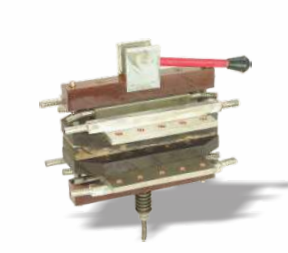

Manual Mechanism

In manual changeover switches, crucible transition is facilitated through a lever mechanism, allowing for manual control and adjustment.

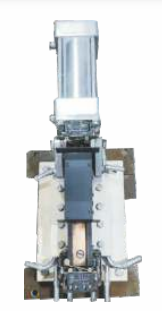

Electrical Mechanism

Electrical changeover switches utilize electromotor power to execute crucible changes efficiently, offering automated functionality for streamlined operations.

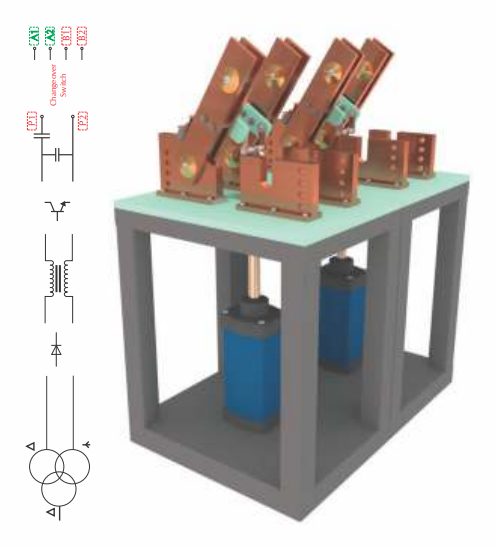

Pneumatic Mechanism

Pneumatic changeover switches employ pneumatic cylinders to transition

crucibles, making them particularly suitable for heavy-duty applications in the

steel industry. This mechanism ensures swift and precise crucible changes,

enhancing overall productivity.

A schematic representation of pneumatic changeover switches with one input and two outputs, manufactured by Lawatherm, exemplifies their robust design and reliable performance.

CHANGE OVERSWITCH

The Lawatherm Change-Over Switch is crafted from high-conductivity copper, meticulously silver-plated to guarantee superior conductivity and durability. Featuring a double-knife contact system, these switches boast heavy contact pressure, ensuring optimal performance and excellent self-cleaning capabilities.

With high short-circuit resistance contacts equipped with double breaking and ample isolating distances, Lawa Change-Over Switches deliver consistent and reliable switching performance. Their robust construction and precise engineering make them ideal for demanding applications where reliability is paramount.

Advantages of Changeover Switch

- SeamlessTransition: Lawatherm Changeover Switches ensure smooth transitions between crucibles connected to feeders, minimizing downtime and maximizing productivity.

- HighPerformance: Manufactured from high-conductivity copper with silver plating, Lawatherm Changeover Switches boast a double knife contact system, ensuring excellent self-cleaning and high performance.

- Reliability: With heavy contact pressure and high short-circuit resistance, Lawatherm Changeover Switches offer reliability and consistency in switching performance, crucial for uninterrupted operations in the steel industry.

Construction of Changeover Switch

Lawatherm Changeover Switches are constructed from high-conductivity copper material, featuring silver plating for enhanced conductivity and durability. The switches utilize a double knife contact system, ensuring robust performance and excellent self-cleaning capabilities. With heavy contact pressure and double-breaking mechanisms, Lawatherm Changeover Switches offer reliable switching operations even under demanding conditions.

Specifications of Changeover Switch:

- Material: High-conductivity copper with silver plating.

- Contact System: Double knife contact system.

- Operation: Manual, electrical, or pneumatic.

- Short-Circuit Resistance: High

- Isolating Distances: Large

- Number of Inputs: 1

- Number of Outputs: 2

Get in touch

Applications:

Lawatherm Changeover Switches find widespread applications in the steel industry, specifically in induction furnace operations. They are utilized for seamlessly switching crucibles connected to feeders, ensuring uninterrupted production processes in steel manufacturing plants.

Installation:

The installation of Lawatherm Changeover Switches should be conducted by trained professionals familiar with the operation and handling of electrical equipment. Proper alignment and connection to the feeder system are essential to ensure optimal performance. Refer to the provided installation manual for detailed instructions.

Maintenance:

Regular maintenance is essential to ensure the continued performance of Lawatherm Changeover Switches. Periodic inspection of contacts, lubrication of moving parts, and cleaning of the switch assembly is recommended to prevent operational issues and

extend the lifespan of the equipment.

Safety Precautions

- Disconnect the power supply before performing any maintenance or installation procedures.

- Use appropriate personal protective equipment (PPE) when handling electrical equipment.

- Ensure proper grounding of the switch and feeder system to prevent electrical hazards.

- Do not attempt to modify or repair the switch without proper training and authorization.

Frequently Asked Questions

A Changeover Switch facilitates the seamless transition of crucibles connected to feeders in induction furnaces, ensuring uninterrupted production processes.

Changeover Switches are available in manual, electrical, and pneumatic mechanisms, catering to different operational requirements in the steel industry.

Lawatherm Changeover Switches should be inspected regularly as per the maintenance schedule provided by the manufacturer. Typically, inspections are recommended on a quarterly basis.

Yes, Lawatherm offers customization options for Changeover Switches to meet the specific needs and preferences of customers in the steel industry.

Prioritize safety by disconnecting power supply, using appropriate PPE, and ensuring proper grounding of the switch and feeder system to mitigate electrical hazards.