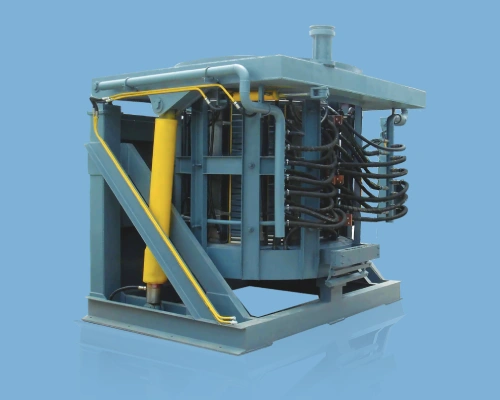

Equipping Steel industry at all Levels

With Over 25 Years Experience Rest Assured You’re In Safe Hands

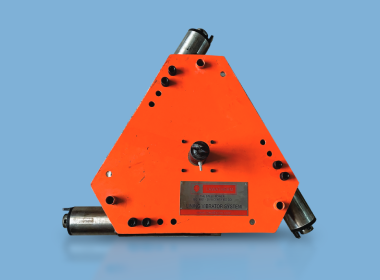

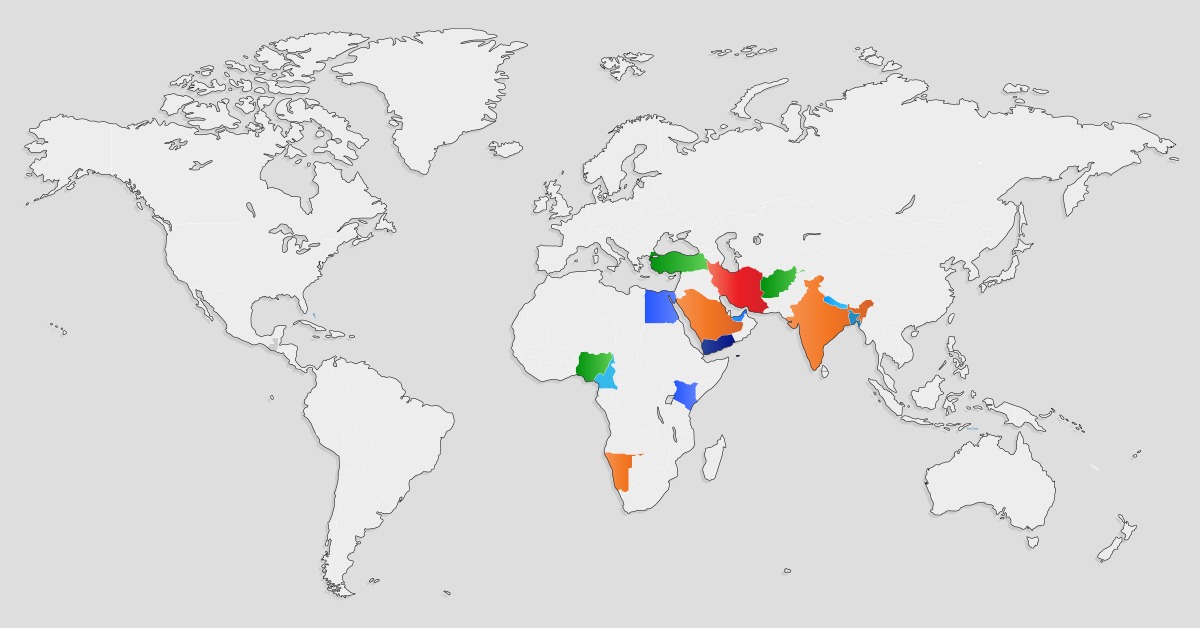

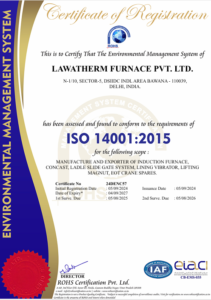

LAWATHERM FURNACE PVT LTD is a multi product and services organization and is contributing to steel power sector dealing in manufacturing, supply, erection, testing and commissioning of and turnkey projects with district ion and credibility. Lawatherm is an upcoming steel melting & handling (EOT crane) spares manufacturing industry and in operation 2 decade ago. Basic idea behind lawatherm have encompassed years of knowledge and expertise in their quest for giving the best value for their customers to produce a superior quality products for steel industries. Read More…