The steel manufacturing process demands high energy, tight control, and precise timing. Every second saved and every degree preserved in heat translates into productivity. This is where Cold Sintering Pre-Heaters are becoming a smart choice for many modern plants. They are reshaping how raw materials are prepared before entering the furnace.

At Lawatherm, we’ve seen firsthand how these systems change the game for both small and large steel units.

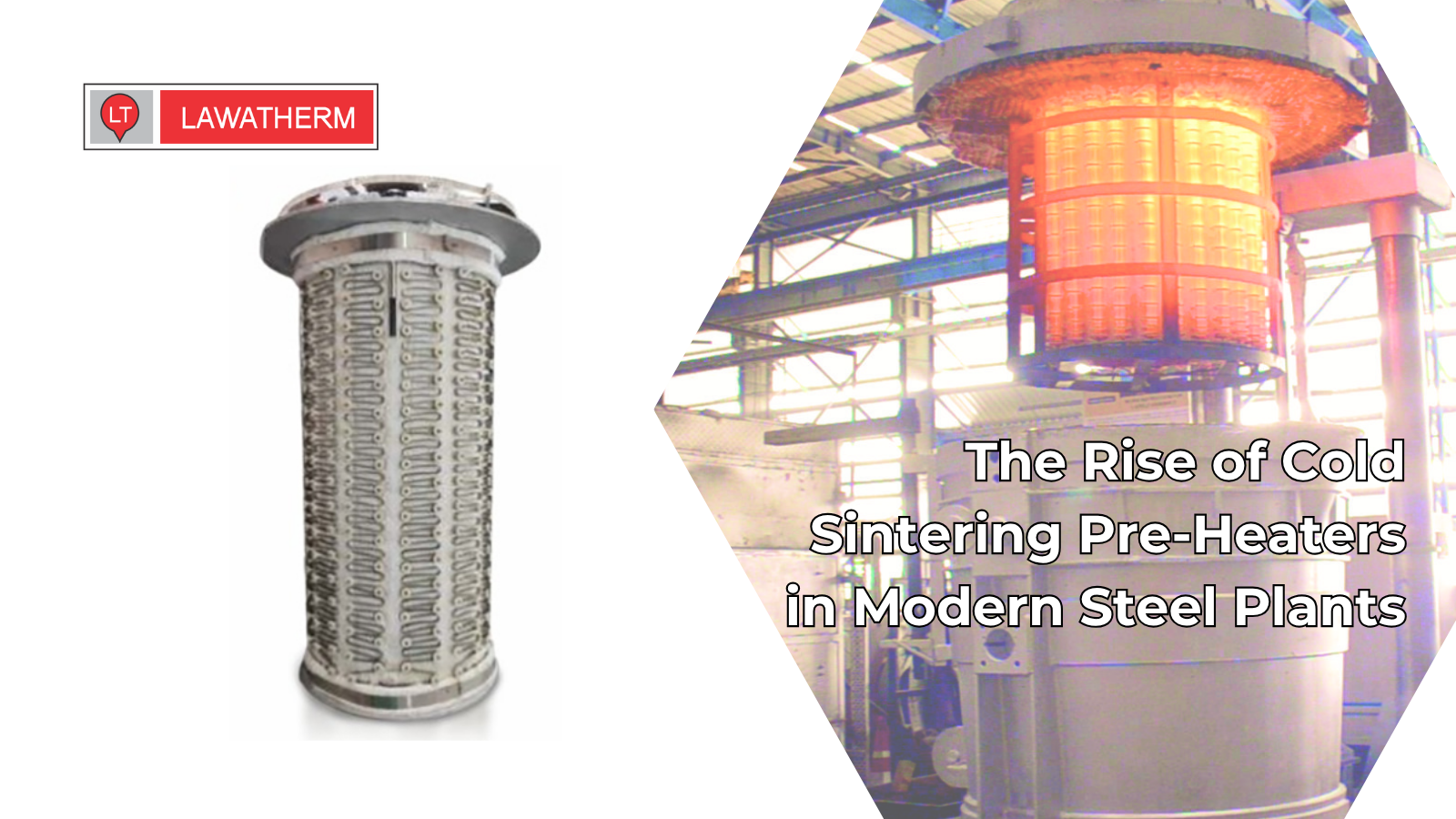

What Are Cold Sintering Pre-Heaters?

Cold Sintering Pre-Heaters are thermal systems used to warm up sinter mix before it enters the furnace. The process involves heating the raw mix to a controlled temperature to boost combustion and reduce fuel consumption. Unlike older methods that allow raw materials to enter the furnace at ambient temperature, these systems ensure a consistent thermal pre-treatment.

Why does that matter? Because cold feed materials lower the temperature inside the furnace. This forces the furnace to burn more fuel to reach melting temperatures. The result? More time, higher costs, and uneven melting.

With Cold Sintering Pre-Heaters, the incoming materials are already hot. The furnace doesn’t have to do all the work. This simple shift improves furnace input efficiency and keeps the process smooth.

The Link Between Pre-Heating and Energy Use

Steel plants face pressure to reduce fuel costs and emissions. The sintering process itself consumes a large amount of energy. Pre-heating tackles this issue by reducing the load on the main furnace.

Here’s how it works in practice:

- The pre-heater uses controlled burners or electric heating systems.

- It raises the temperature of the sinter feed to a level just below combustion.

- This leads to better combustion when the mix enters the main furnace.

- You get quicker ignition, better material flow, and a stable melt.

This small change helps save fuel. Plants using energy-efficient pre-heating systems have reported reduced coke use by up to 10%. That’s a big number when scaled across daily operations.

How Cold Sintering Pre-Heaters Support Quality

Consistency is key in the steel manufacturing process. The more uniform your inputs, the more predictable your outputs. By using Cold Sintering Pre-Heaters, you prepare a sinter mix that behaves consistently in the furnace.

Temperature fluctuations often cause defects. Pre-heated materials remove this variable. They help maintain a steady temperature curve inside the furnace.

This improves the quality of the final steel, reduces scrap, and lowers downtime caused by furnace instability.

At Lawatherm, we help steel plants customize pre-heaters that match their production rate and furnace capacity.

Real-World Benefits of Using Cold Sintering Pre-Heaters

If you run a steel plant, your biggest concerns include time, cost, and reliability. Here’s what Cold Sintering Pre-Heaters offer:

- Faster furnace readiness: The furnace reaches operating temperature quicker.

- Lower fuel bills: Less energy needed to heat cold feed.

- Cleaner combustion: Reduced emissions from stable thermal profiles.

- Reduced wear: Uniform heat reduces stress on furnace lining and parts.

- Better product: Controlled heat flow leads to cleaner, more uniform steel.

One plant we worked with at Lawatherm reported a 12% reduction in fuel use and improved cast quality after installing a custom pre-heater.

Should You Invest in a Cold Sintering Pre-Heater?

Ask yourself:

- Are your fuel costs rising?

- Do you see variable quality in your steel output?

- Is your furnace downtime creeping up?

- Do you want to reduce your plant’s carbon footprint?

If your answer is yes to even one, you might want to look at a Cold Sintering Pre-Heater. It’s not about overhauling your plant. It’s about fixing the weakest link—raw material input.

The upfront cost pays back quickly through fuel savings and higher output consistency.

What Makes a Good Pre-Heater?

A pre-heater should do one thing well: bring your sinter mix to the right temperature—nothing more, nothing less. The right unit depends on your production speed, furnace type, and feed material.

At Lawatherm, we help you select the right size, heat source, and control system. We don’t just ship a product; we design it to fit your existing system. That means smoother setup, faster startup, and better performance.

A Smarter Way to Heat

Cold Sintering Pre-Heaters may look simple, but their role in the steel manufacturing process is growing. They help cut energy waste, improve furnace input efficiency, and deliver more stable operations.

Steel plants are moving fast toward cleaner, smarter practices. If you want your furnace to run longer, cleaner, and more predictably, then it starts before the melt. It starts with pre-heating.

Lawatherm is proud to support this shift with custom thermal pre-treatment systems that meet the needs of today’s steel makers. Let your furnace work smarter, not harder—with the right heat at the right time.