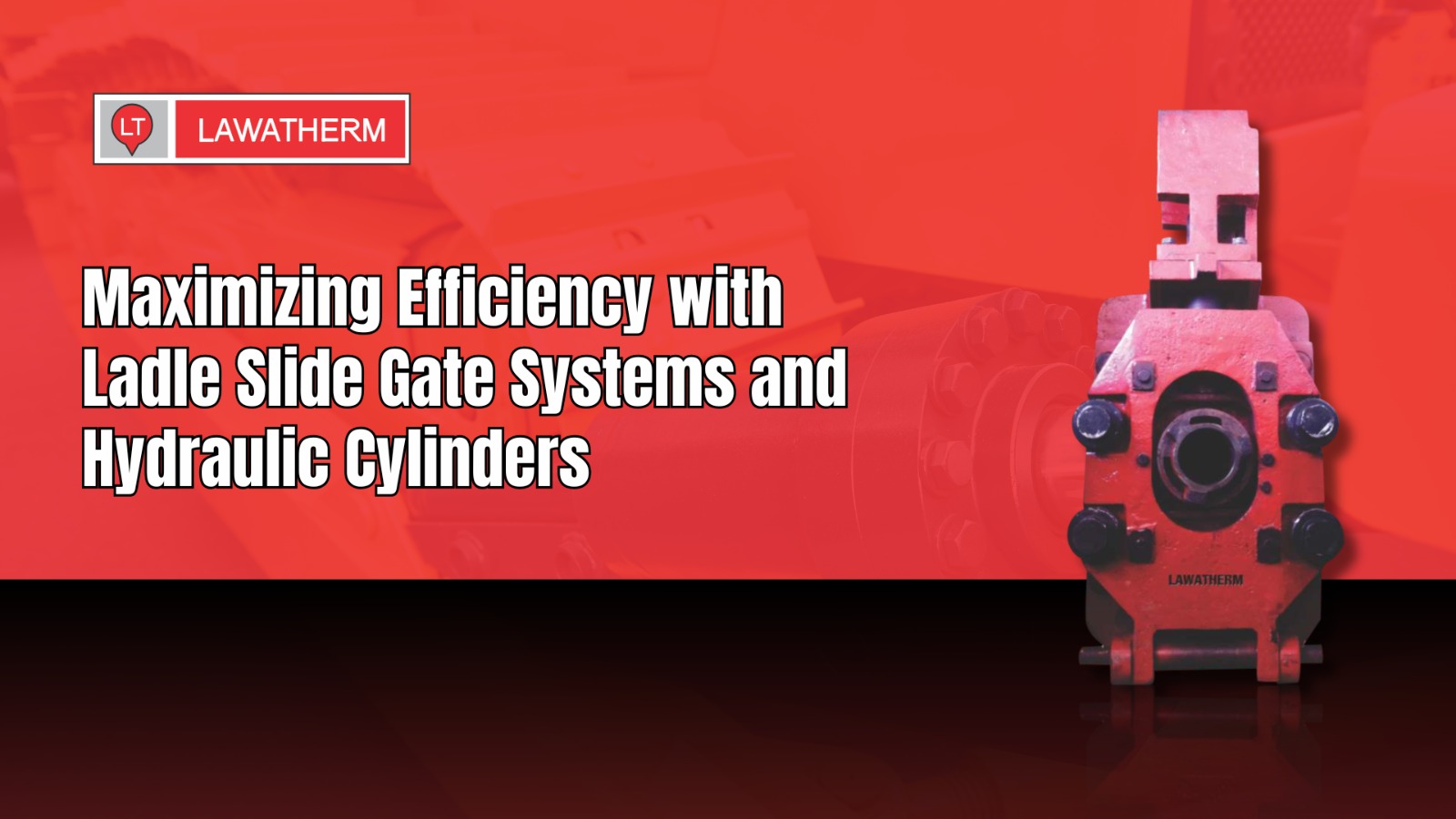

In the steel manufacturing process, efficiency and reliability are paramount. One critical component that enhances operational efficiency in ladle handling is the ladle slide gate system. These systems, often coupled with hydraulic cylinders, play a crucial role in managing molten metal transfer in steel plants. As a leading provider of hydraulic spare parts, Lawatherm understands the importance of these components in achieving optimal performance and ensuring safe operations.

Understanding Ladle Slide Gate Systems

A ladle slide gate system is designed to control the flow of molten metal from a ladle to a casting machine. These systems provide precise control over the pouring process, allowing operators to manage the metal flow rate accurately. They consist of a series of components, including the slide gate, hydraulic actuators, and control systems.

The effectiveness of a ladle slide gate system is heavily dependent on the hydraulic cylinders used to operate the slide gate. Hydraulic cylinders provide the necessary force to open and close the gate, ensuring that the molten metal is poured safely and efficiently. By utilizing high-quality hydraulic spare parts, steel plants can maintain their systems and avoid costly downtimes.

The Role of Hydraulic Cylinders

Hydraulic cylinders are essential for the operation of ladle slide gate systems. These cylinders convert hydraulic energy into mechanical force, allowing for smooth and controlled movement of the slide gate. The design and quality of these cylinders directly impact the overall efficiency of the ladle handling process.

When selecting a hydraulic cylinder for slide gate ladles, several factors should be considered:

- Capacity: The hydraulic cylinder must be capable of handling the required force to operate the slide gate effectively. This includes considering the weight of the molten metal and the size of the ladle.

- Durability: Given the harsh operating conditions in steel plants, the hydraulic cylinder should be made from high-quality materials that can withstand high temperatures and corrosive environments.

- Precision: The ability to control the flow of molten metal precisely is vital for maintaining product quality and ensuring safety. A well-designed hydraulic cylinder will allow for smooth and accurate movement of the slide gate.

- Maintenance: Choosing a hydraulic cylinder that requires minimal maintenance can significantly reduce operational costs. Regular inspections and timely replacement of worn-out components are crucial for maintaining system efficiency.

Benefits of Effective Ladle Slide Gate Systems

Implementing an efficient ladle slide gate system can lead to numerous benefits for steel manufacturers:

- Improved Control: The ability to control the flow of molten metal accurately helps reduce waste and ensures that the right amount of metal is poured during the casting process.

- Increased Safety: Properly functioning ladle slide gate systems minimize the risk of spills and accidents, contributing to a safer working environment for operators.

- Higher Productivity: Efficient handling of molten metal allows for faster turnaround times and increased production rates. When the hydraulic cylinders and slide gate systems work seamlessly together, steel plants can achieve optimal operational performance.

- Reduced Downtime: By investing in quality hydraulic spare parts, manufacturers can minimize the risk of breakdowns and extend the lifespan of their ladle slide gate systems. Regular maintenance and timely upgrades are essential for keeping these systems running smoothly.

The Role of Lawatherm

At Lawatherm, we are committed to providing high-quality solutions for steel manufacturers. Our range of hydraulic spare parts includes durable and reliable hydraulic cylinders designed specifically for ladle slide gate systems. We understand the unique challenges faced by steel plants and strive to deliver products that enhance efficiency, safety, and performance.

Our team of experts is available to assist clients in selecting the right components for their operations. With extensive industry knowledge and a commitment to quality, Lawatherm is a trusted partner in maximizing the efficiency of ladle handling processes.

Conclusion

In the steel manufacturing process, every component plays a vital role in ensuring efficiency and safety. The integration of a reliable ladle slide gate system with high-quality hydraulic cylinders can significantly enhance operational performance. By focusing on precision, durability, and proper maintenance, steel plants can optimize their processes and achieve higher productivity.

At Lawatherm, we are dedicated to providing the best solutions for steel manufacturers. Our commitment to quality and service ensures that your ladle slide gate systems and hydraulic spare parts are always operating at peak performance. By investing in reliable equipment and maintenance practices, you can maximize efficiency and ensure the success of your operations in the competitive steel industry.