In a steel plant’s complex and demanding environment, selecting the appropriate hydraulic cylinder for your slide gate ladle system is crucial. Hydraulic cylinders are integral to the operation of ladle slide gate systems, ensuring precise control and reliability in the metal casting process. With many options available, choosing the right hydraulic cylinder can significantly impact the efficiency and longevity of your equipment. In this guide, we’ll delve into the key considerations for selecting the best hydraulic cylinder for slide gate ladle systems, focusing on hydraulic spare parts, ladle slide gate systems, and their importance to steel plant manufacturers.

Understanding Slide Gate Ladle Systems

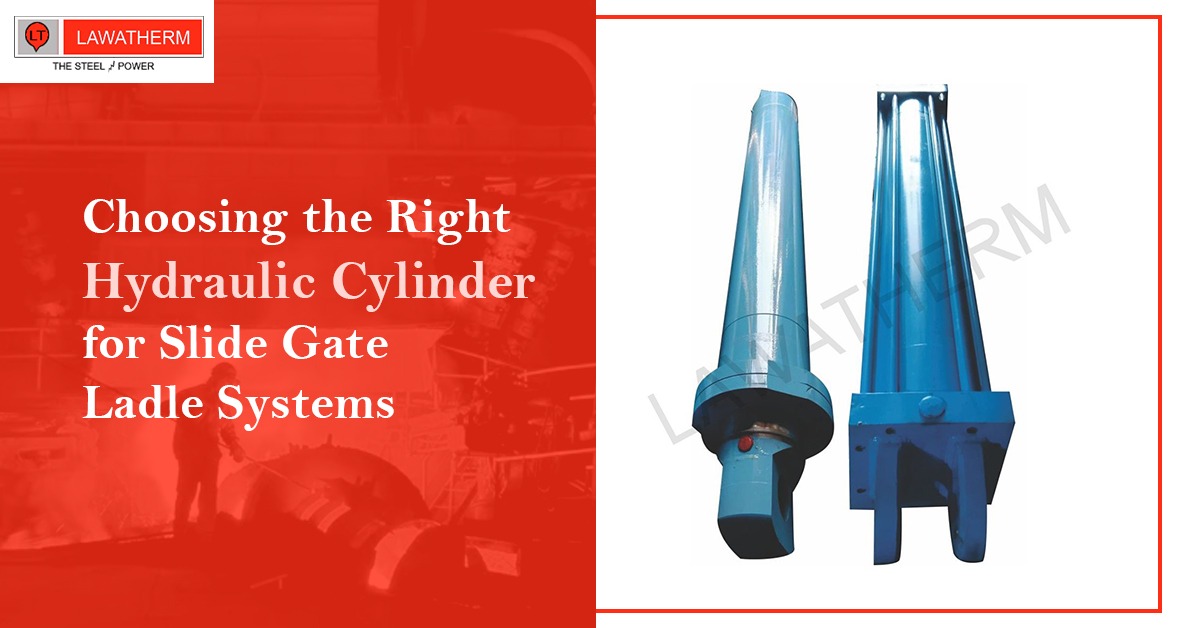

Slide gate ladle systems play a pivotal role in steel plants, regulating the flow of molten metal from the spoon to the casting mold. These systems require robust and precise components to withstand extreme conditions and ensure seamless operations. Hydraulic cylinders, a critical component of these systems, provide the necessary force and control to operate the slide gates efficiently.

Key Considerations for Choosing Hydraulic Cylinders

- Load Capacity and Force Requirements: The hydraulic cylinder must be capable of handling the load and force requirements of the slide gate system. Calculating the precise load and force needed based on the spoon’s size and the type of metal being processed is essential. Overloading the cylinder can lead to premature wear and failure, disrupting operations and causing costly downtime.

- Durability and Material Quality: Given the harsh operating conditions in steel plants, the durability and material quality of hydraulic cylinders are paramount. Cylinders made from high-grade materials, such as hardened steel or corrosion-resistant alloys, can withstand intense heat and pressure. Opting for durable and high-quality hydraulic spare parts ensures the longevity and reliability of the slide gate ladle system.

- Precision and Control: Precision and control are critical for the effective operation of ladle slide gate systems. Hydraulic cylinders with precise control mechanisms allow for smooth and accurate movements of the slide gate, ensuring consistent flow rates and minimizing metal wastage. Look for cylinders with advanced control features, such as proportional valves or feedback systems, to enhance operational precision.

- Maintenance and Serviceability: Ease of maintenance and serviceability are crucial factors in choosing hydraulic cylinders. Regular maintenance is necessary to keep the cylinders in optimal condition and prevent unexpected failures. Selecting cylinders that are easy to service and have readily available spare parts can minimize downtime and reduce maintenance costs.

- Compatibility with Existing Systems: Ensuring compatibility with existing slide gate ladle systems is vital when selecting hydraulic cylinders. Compatibility issues can lead to installation challenges and operational inefficiencies. Consulting with experienced steel plant manufacturers, like Lawatherm, can help identify hydraulic cylinders that seamlessly integrate with your current setup.

Why Choose Lawatherm for Your Hydraulic Cylinder Needs?

At Lawatherm, we specialize in providing top-quality hydraulic cylinders and spare parts for slide-gate ladle systems. With years of experience in the steel plant manufacturing industry, we understand the unique challenges and requirements of our clients. Our hydraulic cylinders are designed to deliver exceptional performance, durability, and precision, ensuring your operations run smoothly and efficiently.

Conclusion

Choosing the right hydraulic cylinder for your slide gate ladle system is a critical decision that can impact the efficiency and longevity of your steel plant operations. By considering factors such as load capacity, durability, precision, maintenance, and compatibility, you can make an informed choice that meets your specific needs. Partnering with a trusted provider like Lawatherm ensures you receive high-quality hydraulic cylinders and expert support, enabling you to achieve optimal performance in your metal casting processes.