Induction furnaces’ efficiency and performance depend largely on the quality of their components. The Induction Furnace Yoke plays a pivotal role in enhancing operational capabilities. This blog delves into the two main types of yokes used in induction furnaces: the induction heater and the lamination yoke. By understanding their functions and benefits, steel plant manufacturers can optimize their operations while leveraging high-quality products from Lawatherm.

Understanding Yokes in Induction Furnaces

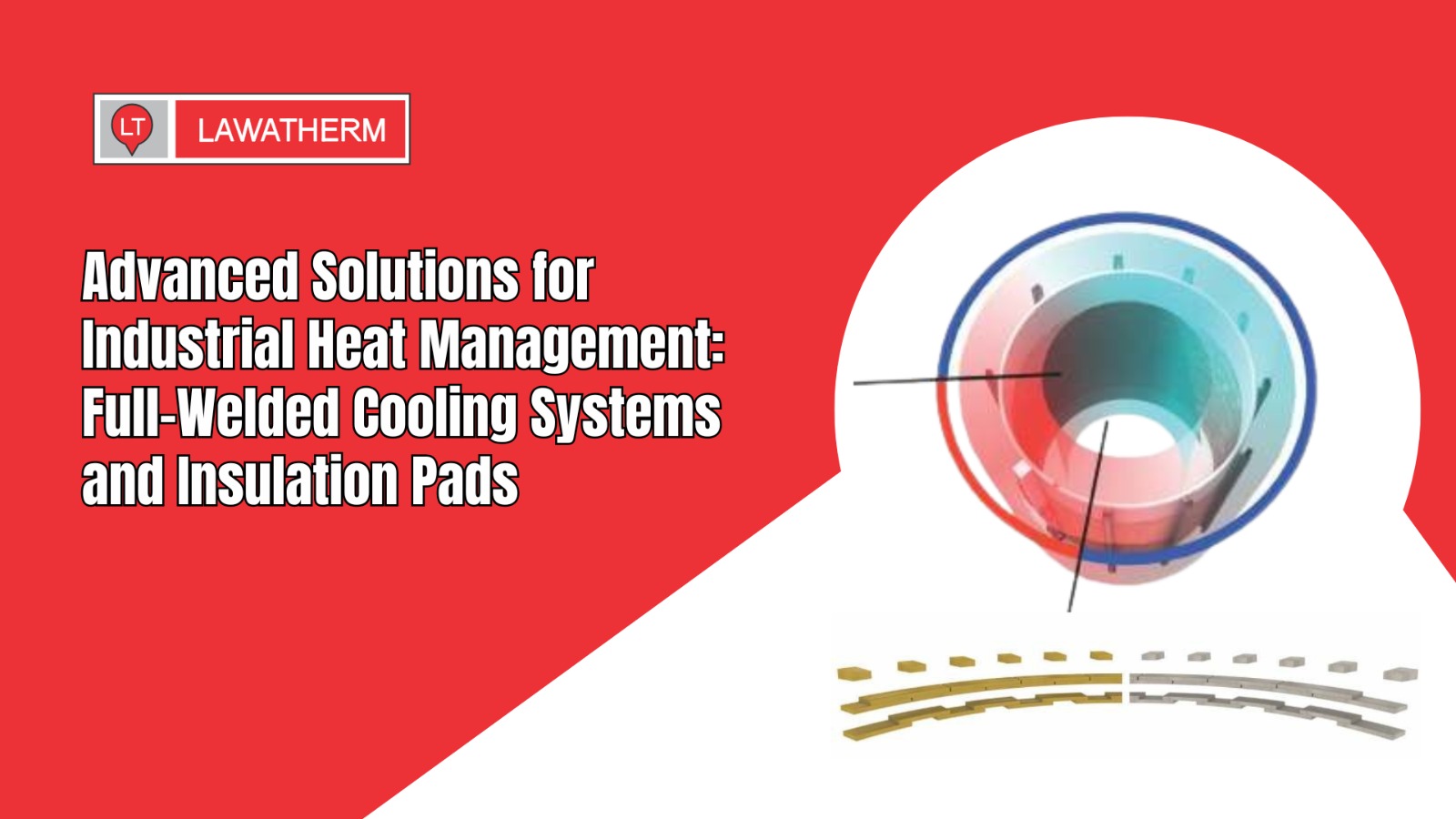

To understand the role of yokes, it’s important to first consider the furnace working principle. Induction furnaces rely on electromagnetic fields to generate heat, and the yoke plays a key part in shaping and directing that field. The yoke is a critical part of a magnetic furnace, helping direct the magnetic field required for heating metals. The yoke in an induction furnace is a crucial magnetic component that helps direct and enhance the magnetic field generated during the heating process. The efficiency of induction heating heavily relies on the design and material of the yoke. Choosing the right type of yoke can significantly impact energy consumption, heating speed, and overall furnace performance.

Induction Heater Yoke

The Induction Heater Yoke works alongside the furnace magnet to intensify the magnetic field around the coil. The power yoke is designed to handle high energy loads, making it essential for heavy-duty melting operations. The Induction Heater Yoke is specifically designed to improve the magnetic field’s concentration around the induction coil. This type of yoke helps facilitate efficient heat transfer to the metal being melted or heated. Here are some key features and benefits of induction Heater Yokes:

- Enhanced Magnetic Efficiency: The design of the Induction Heater Yoke allows for optimal magnetic flux concentration, which results in improved energy efficiency. This means that less energy is wasted, leading to cost savings in the long run.

- Improved Heating Rates: By effectively directing the magnetic field, Induction Heater Yokes enable faster heating rates. This can lead to shorter processing times, allowing steel plant manufacturers to increase production efficiency.

- Durability and Reliability: High-quality materials used in the construction of these yokes ensure they can withstand the intense conditions within the furnace. This durability translates to longer service life, reducing the frequency of replacements and maintenance.

- Versatility: Induction heater yokes can be designed to accommodate various sizes and configurations of induction coils, making them suitable for a wide range of applications in steel manufacturing.

Lamination Yoke

On the other hand, the Lamination Yoke is engineered to minimize eddy currents and hysteresis losses, which can adversely affect the efficiency of the induction heating process. The Lamination Furnace Yoke features layered construction that offers unique advantages:

- Reduced Eddy Currents: The laminated structure of the Lamination Yoke restricts the flow of eddy currents, thereby reducing energy losses. This results in improved overall efficiency and lower operational costs.

- High Magnetic Performance: Laminated yokes provide excellent magnetic properties, ensuring effective magnetic coupling between the induction coil and the workpiece. This is crucial for achieving optimal melting and heating performance.

- Customization Options: Just like the Induction Heater Yoke, Lamination Yokes can be tailored to meet specific operational requirements. Steel plant manufacturers can work with suppliers like Lawatherm to develop yokes that suit their unique furnace designs and processes.

- Weight Reduction: The lamination process not only enhances performance but also reduces the weight of the yoke. A lighter yoke can lead to lower structural stress on the induction furnace, contributing to a longer equipment lifespan.

Choosing the Right Yoke for Your Furnace

Partnering with an experienced furnace spare parts supplier like Lawatherm ensures access to high-quality products and knowledgeable support. For Hindi-speaking users, a common query is “योक के निर्माण को क्या कहते हैं”, referring to the process of yoke construction and its role in induction heating. When selecting between an induction heater Yoke and a lamination Yoke, several factors should be considered:

- Application Requirements: The intended use of the induction furnace plays a critical role in determining the suitable type of yoke. If rapid heating and energy efficiency are top priorities, an induction heater yoke may be more appropriate. Conversely, for applications where minimizing energy losses is essential, a Lamination Yoke may be the better choice.

- Cost Considerations: While both types of yokes can lead to cost savings through improved efficiency, their initial investment may vary. Manufacturers should evaluate their budget about the potential long-term savings associated with each type.

- Compatibility with Existing Equipment: Ensuring that the chosen yoke is compatible with the existing induction system is vital. Lawatherm provides a range of customizable solutions to fit various induction furnace designs, making it easier for manufacturers to find the right fit.

- Supplier Expertise: Partnering with an experienced supplier like Lawatherm ensures access to high-quality products and knowledgeable support. This can greatly influence the performance and longevity of the induction furnace system.

Conclusion

The selection of the right yoke is crucial for optimizing the performance of induction furnaces. Whether you opt for the efficiency of the Induction Heater Yoke or the energy-saving benefits of the Lamination Yoke, understanding their features and advantages is essential. By choosing yokes from a reputable supplier like Lawatherm, steel plant manufacturers can enhance their operational efficiency, reduce costs, and ensure the longevity of their equipment. Investing in advanced yokes is a step towards achieving superior performance in induction heating applications, ultimately contributing to the overall success of steel manufacturing processes. For detailed design references, users often consult resources like an Inductotherm furnace manual PDF free download, which outlines yoke configurations and technical guidelines. Users may also refer to documents like the Electrotherm furnace manual PDF when assessing component compatibility and system layouts.