Precise control during steel pouring is critical. One wrong move, and the entire melt could be compromised. That’s where a ladle slide gate system becomes essential. In high-temperature furnace operations, this system offers direct control over the flow of molten metal, improving accuracy, safety, and performance. At Lawatherm, we understand how important this control is to your bottom line.

What Is a Ladle Slide Gate System?

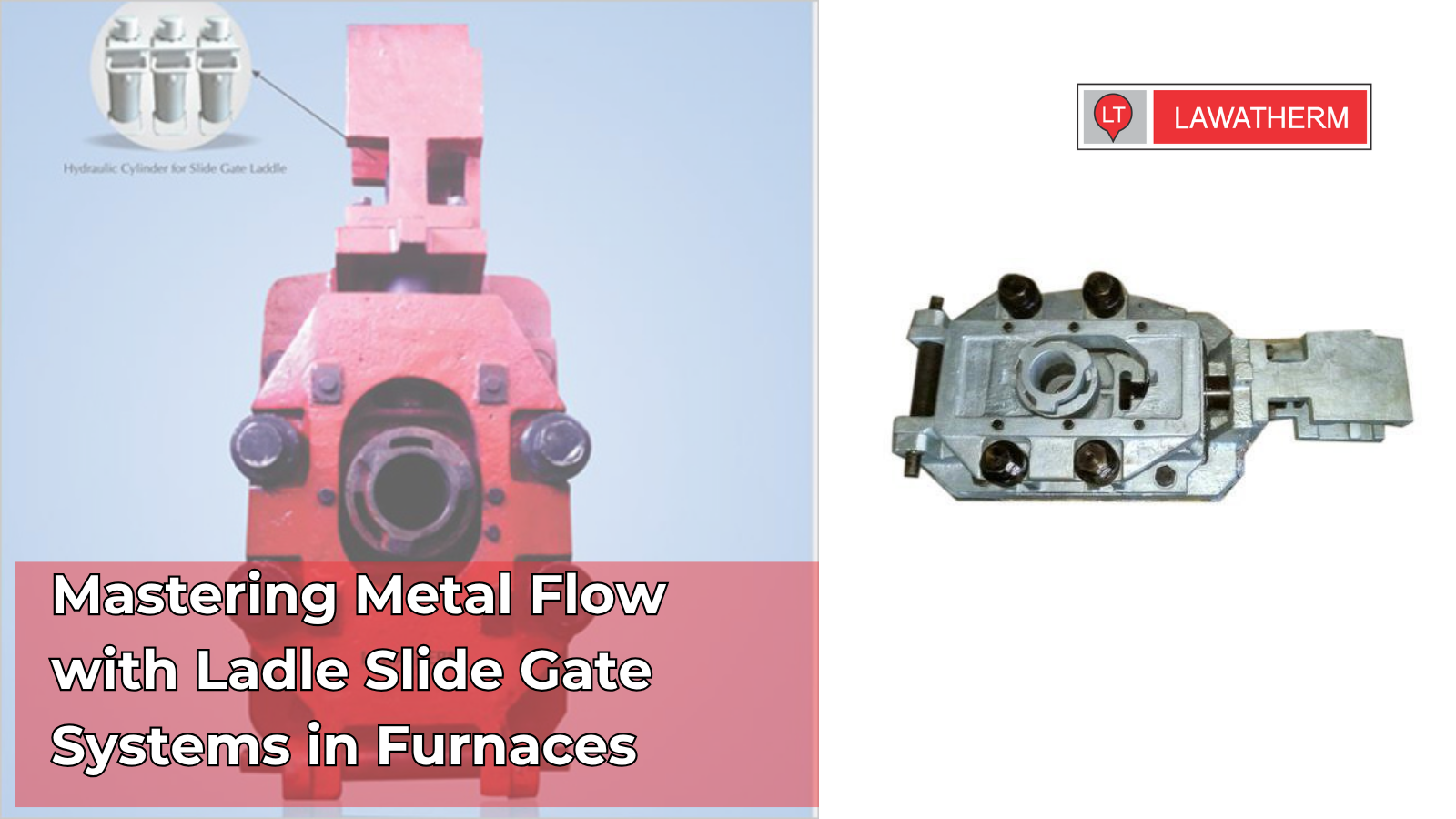

A ladle slide gate system is a mechanical assembly fitted at the bottom of the ladle. Its main function is to regulate the release of molten metal during tapping. The core component—refractory slide gates—moves horizontally to open or close the metal flow. This setup gives you better controlled metal flow, reducing risks and improving the pour’s accuracy.

Without this system, operators rely on older, less precise methods like stopper rods or manually lifting gates, which pose serious safety hazards and can waste valuable material.

Why Controlled Metal Flow Matters

Steel casting is not just about pouring liquid metal into a mold. It’s about controlling the volume, speed, and timing. The ladle slide gate system allows you to control the melt stream in real time.

This matters most when:

- Pouring into continuous casting machines

- Filling complex molds

- Adjusting flow to prevent mold overflow

With better steel pouring control, defects like cold shuts, misruns, or gas entrapment decrease. That leads to better product quality and fewer rejections.

Key Components of the System

Let’s break down the core parts of the ladle slide gate system:

- Refractory slide gates: These are high-temperature bricks or plates that move to open or close the metal outlet.

- Housing plate: Holds the gate in place and allows for movement.

- Lever mechanism or hydraulic actuator: Enables the gate movement, either manually or automatically.

- Nozzle: Directs the flow into the tundish or mold.

Each part must work in sync. Fault in one area compromises the entire tapping system. That’s why every component, including furnace spare parts, needs regular inspection and timely replacement.

Role in Furnace Safety

Controlling molten metal isn’t just about product quality—it’s about keeping your team safe. Uncontrolled flow can cause splashing, overflows, and even explosions when metal contacts moisture.

The ladle slide gate system reduces these risks by giving you better command over the release. Operators can stop the flow instantly if needed, avoiding accidents during pouring or transfer.

Do you ever feel your team struggles with poor visibility or sudden gushes of metal during tapping? A well-maintained gate system can solve that.

Choosing the Right System

Not all ladle slide gate systems are the same. Your choice depends on:

- Ladle size

- Pouring frequency

- Type of steel or alloy

- Expected wear cycle

For high-volume plants, automated systems with hydraulic actuators offer better repeatability. In smaller foundries, manual lever-operated systems may suffice. The key is to pick a system that matches your operation without overcomplicating it.

At Lawatherm, we help you assess your specific needs before offering a solution. Our support doesn’t end at supply. We offer guidance on installation, use, and maintenance.

Importance of Furnace Spare Parts

Each part in your ladle slide gate system is exposed to extreme heat, pressure, and wear. Regular maintenance is non-negotiable. If you’re replacing just the gate plate but ignoring worn levers or cracked housings, you’re risking the whole setup.

Having the right furnace spare parts on hand helps you avoid downtime. These include:

- Slide plates

- Wear plates

- Nozzles

- Actuation parts

Always choose spares that match the original specs. Don’t go for generic fits that could fail under pressure. At Lawatherm, we stock high-quality furnace spare parts made to withstand the rigors of continuous casting and foundry operations.

Common Issues and Fixes

Every system develops issues over time. Here are common ones to watch:

- Sticking gates: Caused by metal build-up or misalignment. Clean regularly and check the plate surfaces.

- Leakage: Usually from worn refractory slide gates. Replace before metal starts leaking during a pour.

- Actuator failure: Happens when seals wear out or the handle mechanism bends. Inspect after every shift in high-use plants.

Do your teams have a routine check system? If not, start small. Weekly checks can prevent costly shutdowns.

Real-World Results

Steel plants using ladle slide gate systems report faster turnaround times and fewer casting defects. One plant in central India cut its mold rejection rate by 18% after switching from stopper rod systems to refractory slide gates with real-time flow control.

Another plant reduced tapping time per ladle by 30 seconds. That might sound small, but over a week, it adds up to hours saved.

Let Lawatherm Support Your Operations

Lawatherm delivers durable ladle slide gate systems tailored to your plant’s requirements. Whether you’re running high-volume casting lines or small-batch furnaces, we’ve got solutions that help you maintain controlled metal flow with confidence.

Need a custom spare part or full gate assembly? We offer both standard and made-to-fit systems along with ongoing support. Our products are tested for extreme temperature resistance, smooth operation, and reliable shut-off.

Don’t wait for a leak to upgrade your system. Work with Lawatherm and stay in control from ladle to mold.

Final Thoughts

Mastering metal flow starts with the right tools. The ladle slide gate system is one of the most critical tools in any foundry or steel plant. With precise steel pouring control, quality improves, risks drop, and output increases. Back it up with quality furnace spare parts, and your system stays reliable longer.

If you’re ready to take control of your melt flow, talk to Lawatherm today.