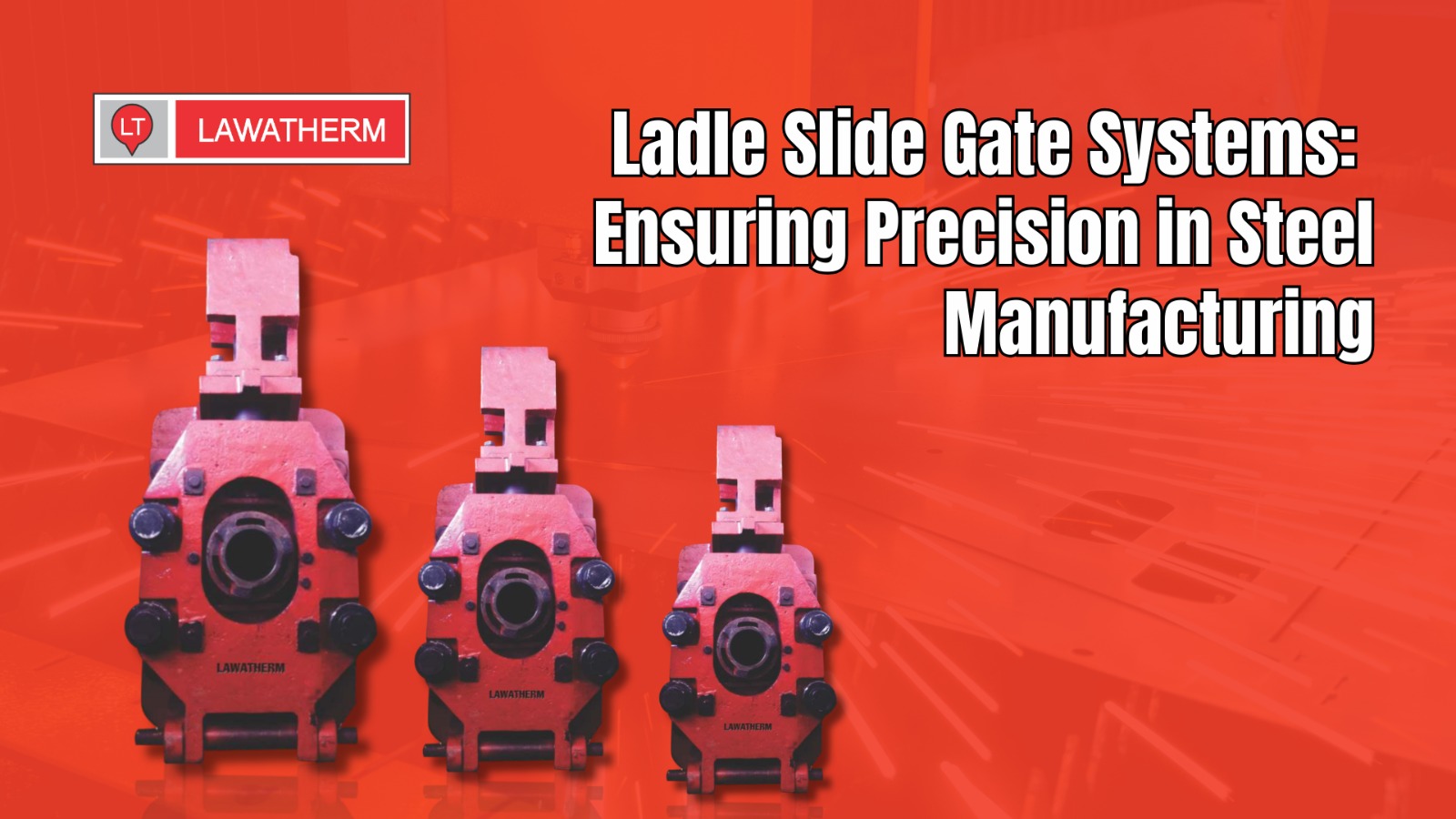

Steel plants don’t get second chances when it comes to molten metal. Once the furnace is fired and the ladle is full, every second, every drop counts. That’s where ladle slide gate systems come in—they manage the flow of molten steel at a point where control is absolutely non-negotiable.

These systems aren’t talked about often. But inside a working steel plant, they do one of the most important jobs—ensuring the controlled release of liquid metal into molds or tundishes. The steel manufacturing process depends on this kind of consistency. And you know what? It shows in the final product.

Why Flow Control Isn’t Optional

At the base of the ladle, the ladle slide gate system is what decides how, when, and how much molten steel gets released. It’s simple to explain, not so simple to design or maintain.

When it works well, there’s:

- No excess spillage

- Less thermal shock

- Cleaner molds

- Fewer interruptions

If you’re running a plant, you’ve likely seen what happens when that control slips. It slows everything down. Sometimes it costs more than just time.

Now think about how many heats a day you run. Multiply that by the volume of steel you move. You can’t afford to guess whether your slide gate is going to hold.

Where It Fits in the Steelmaking Process

Most modern plants rely on induction furnace components for clean, controlled melting. Once the steel reaches pouring temperature, that’s when the ladle comes in.

Here’s where it gets interesting—ladle slide gate systems and induction furnace components aren’t two separate topics. They depend on each other. The gate system helps finish what the furnace starts. The cleaner the flow from the ladle, the less turbulence in the mold. That means fewer inclusions, better surface quality, and less scrap.

It’s not about one perfect component. It’s about how everything works together.

What Makes a Good Slide Gate System?

You can buy cheap. You’ll replace it often. Or you can choose something designed to last longer than just a few cycles. Here’s what to look for:

- Accurate flow control. The steel needs to pour exactly when and where it should.

- Thermal resistance. These parts face extreme heat. Weak materials won’t survive.

- Durability. You want fewer shutdowns, not more.

- Safety. Good systems protect your team, not just your bottom line.

At Lawatherm, we manufacture ladle slide gate systems to handle all of that. Nothing fancy—just reliable performance, shift after shift.

How It Affects the Bigger Picture

We’ve worked with enough plant managers to know—downtime doesn’t always come from where you expect it. Sometimes it’s a single stuck slide gate that halts everything. And once that happens, you’re not just losing hours. You’re wasting power, risking quality, and scrambling to reschedule pours.

High-quality slide gate systems may not look like a major upgrade at first. But over time, they give you back control. They give your team consistency. And that kind of stability? It adds up.

A Quick Word About Trends

There’s always something new on the market—automated actuators, remote operation setups, smarter refractory materials. Some of it’s useful. Some of it… maybe not right now.

We’re testing a few upgrades ourselves at Lawatherm. Our goal isn’t to chase trends. It’s to build tools that actually help steel manufacturers make better decisions and better steel.

What You Can Do Next

Take five minutes. Walk over to your ladle area. What’s the condition of your slide gate system?

If you’re seeing leakage, hard-to-move actuators, or irregular flow—it’s time to do something. And if you’re not sure where to start, that’s where we come in.

We don’t just supply ladle slide gate systems. We also provide core induction furnace components that work alongside them. It means fewer mismatched parts. Fewer vendors. One less thing to worry about.