Manufacturers & Suppliers of Induction Furnace Yoke Products

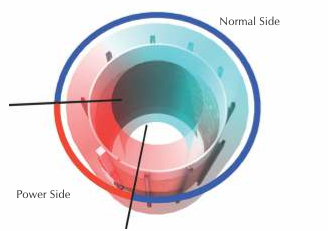

The Induction Furnace Yoke, also known as magnetic yokes or shunts, plays a crucial role in the operation of induction furnaces by collecting and conducting the magnetic field produced by the coil. Lawatherm Furnace Pvt Ltd specializes in manufacturing high-quality induction furnace yokes using cutting-edge technology and experienced staff. These yokes are designed to enhance furnace efficiency, minimize thermal losses, and ensure uniformity of magnetic flux dispersion.

Get in touch

Magnetic Yokes (Shunts) of Induction Furnace

Induction Furnace Yokes play a pivotal role in collecting and conducting the magnetic field generated by the coil. Our Induction Heater Yokes, crafted with precision and expertise, ensure optimal furnace efficiency and minimal thermal losses. Lawatherm offers a range of Induction Heater Yokes tailored to meet specific application requirements, employing cutting-edge technology and experienced craftsmanship.

Core:

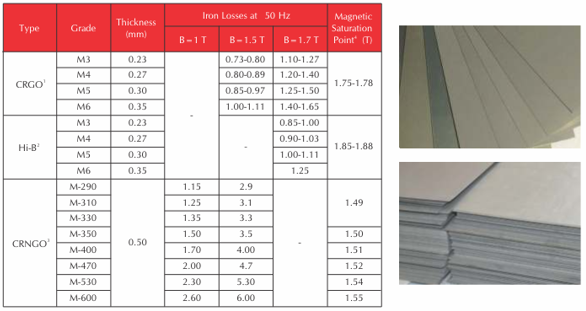

The core of an Induction Furnace Yoke comprises magnetic sheets of varying materials, influencing magnetic permeability, energy losses, and overall furnace efficiency. Lawatherm’s Core solutions are meticulously designed, taking into account factors such as sheet thickness, silicon content, and magnetic saturation point to enhance performance and longevity.

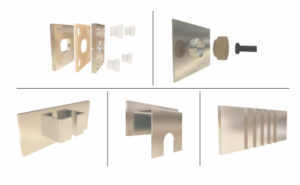

Yoke Base:

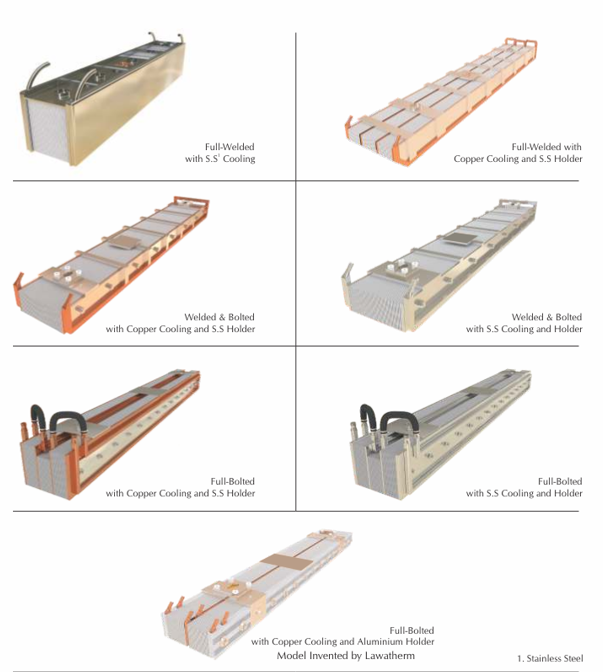

The foundation upon which the yoke rests, the Yoke Base is crucial for stability and performance. Lawatherm offers both flat and curvature-based Yoke Bases, each with its unique advantages. Our innovative designs, such as Full-Welded 1 with S.S Cooling, ensure mechanical stability while preventing dust accumulation and short circuits, delivering unparalleled reliability and efficiency.

Cooling System

Efficient thermal management is essential for sustained operation, especially in high-demand environments. Lawatherm’s Cooling Systems are tailored to facilitate optimal heat dissipation, preserving core integrity and maximizing performance. With features like Full-Welded 1 with S.S. Cooling, our systems ensure reliable operation even under challenging conditions.

Get in touch

Assembly of the Yoke

The assembly of the Induction Furnace Yoke is critical for its structural integrity and performance. Lawatherm offers versatile assembly options, including both bolted and welded configurations. Our advanced techniques and quality craftsmanship ensure seamless integration and minimal energy losses, guaranteeing exceptional reliability and longevity.

The connector of the Yoke:

The connector serves as the interface between the yoke and the supporting structure, facilitating secure attachment and disassembly when needed. Lawatherm provides a range of connector solutions tailored to specific furnace setups. Whether it’s “Push” models for straightforward installations or “Push-Pull” models for added flexibility, our connectors ensure hassle-free operation and maintenance.

Experience the epitome of performance and reliability with Lawatherm’s comprehensive range of Induction Furnace Yoke products. Designed to exceed expectations, our solutions empower industries to achieve unparalleled efficiency and productivity.

Advantages of Induction Furnace Yoke Products:

- Enhanced furnace efficiency and lower thermal losses.

- Improved uniformity of magnetic flux dispersion.

- Customized designs based on customer requirements or application conditions.

- Utilization of high-quality materials and advanced manufacturing processes.

Construction of Induction Furnace Yoke Products:

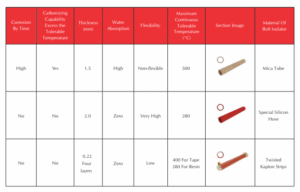

The core of the induction furnace yoke comprises magnetic sheets of various materials, including cold-rolled grain-oriented and non-grain-oriented sheets. The quality and thickness of these sheets significantly impact magnetic permeability, flux integration, and energy losses, thereby affecting furnace efficiency. Lawatherm utilizes advanced materials and techniques to ensure optimal core construction, resulting in superior performance and durability.

Specifications of Induction Furnace Yoke Products:

- Thickness and composition of magnetic sheets.

- Magnetic permeability and flux integration.

- Maximum magnetic field intensity for different core sheets.

- Design features such as curvature-based yoke bases for mechanical stability and prevention of dust attraction.

Application of Induction Furnace Yoke Products:

Induction Furnace Yokes manufactured by Lawatherm are utilized in various industries, including steel plants, foundries, and metal processing facilities. They are essential components for melting and casting processes, ensuring efficient operation and consistent product quality.

Installation of Induction Furnace Yoke Products:

Lawatherm provides detailed guidelines and instructions for the installation of induction furnace yokes. Proper installation is essential for optimizing performance and preventing potential issues such as short circuits or mechanical instability. Special insulation pads are available to address specific installation requirements and ensure long-term reliability.

Maintenance of Induction Furnace Yoke Products:

Regular maintenance is essential to ensure the continued performance and longevity of induction furnace yokes. Lawatherm recommends periodic inspection and cleaning to remove dust and debris that may accumulate around the yoke. Additionally, monitoring cooling system effectiveness and addressing any potential issues promptly can help prevent overheating and ensure uninterrupted operation.

Safety Precautions of Induction Furnace Yoke Products:

Lawatherm emphasizes the importance of adhering to safety precautions when handling or operating induction furnace yokes. Proper training and protective equipment should be provided to personnel involved in installation, maintenance, or repair activities. Measures should be taken to minimize exposure to high temperatures, electrical hazards, and potential mechanical hazards.

Frequently Asked Questions

Induction furnace yokes are typically constructed using magnetic sheets of various materials, including cold-rolled grain-oriented (CRGO) and non-grain-oriented (CRNGO) sheets. These materials are selected for their magnetic properties, durability, and resistance to thermal stress.Content

Induction furnace yokes play a critical role in collecting and conducting the magnetic field produced by the coil, which is essential for the induction heating process. High-quality yokes with optimized construction and design help enhance furnace efficiency by minimizing energy losses and ensuring uniformity of magnetic flux dispersion.

During installation, it’s important to follow manufacturer guidelines and ensure proper alignment and attachment of the yoke to the furnace coil. Additionally, attention should be paid to the cooling system to ensure effective heat dissipation and prevent overheating.

Regular inspection and maintenance are essential to ensure the continued performance and longevity of induction furnace yokes. Lawatherm recommends periodic inspections to check for signs of wear, damage, or buildup of dust and debris. Maintenance activities may include cleaning, lubrication, and replacement of worn components as needed.

When handling or operating induction furnace yokes, personnel should wear appropriate protective equipment, including heat-resistant gloves, safety goggles, and protective clothing. Care should be taken to avoid exposure to high temperatures, electrical hazards, and potential mechanical hazards associated with the equipment.

Lawatherm Furnace Pvt Ltd is committed to providing high-quality induction furnace yokes tailored to meet the needs of customers across various industries. With a focus on innovation, reliability, and customer satisfaction, Lawatherm aims to be the preferred choice for induction furnace solutions worldwide.